September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

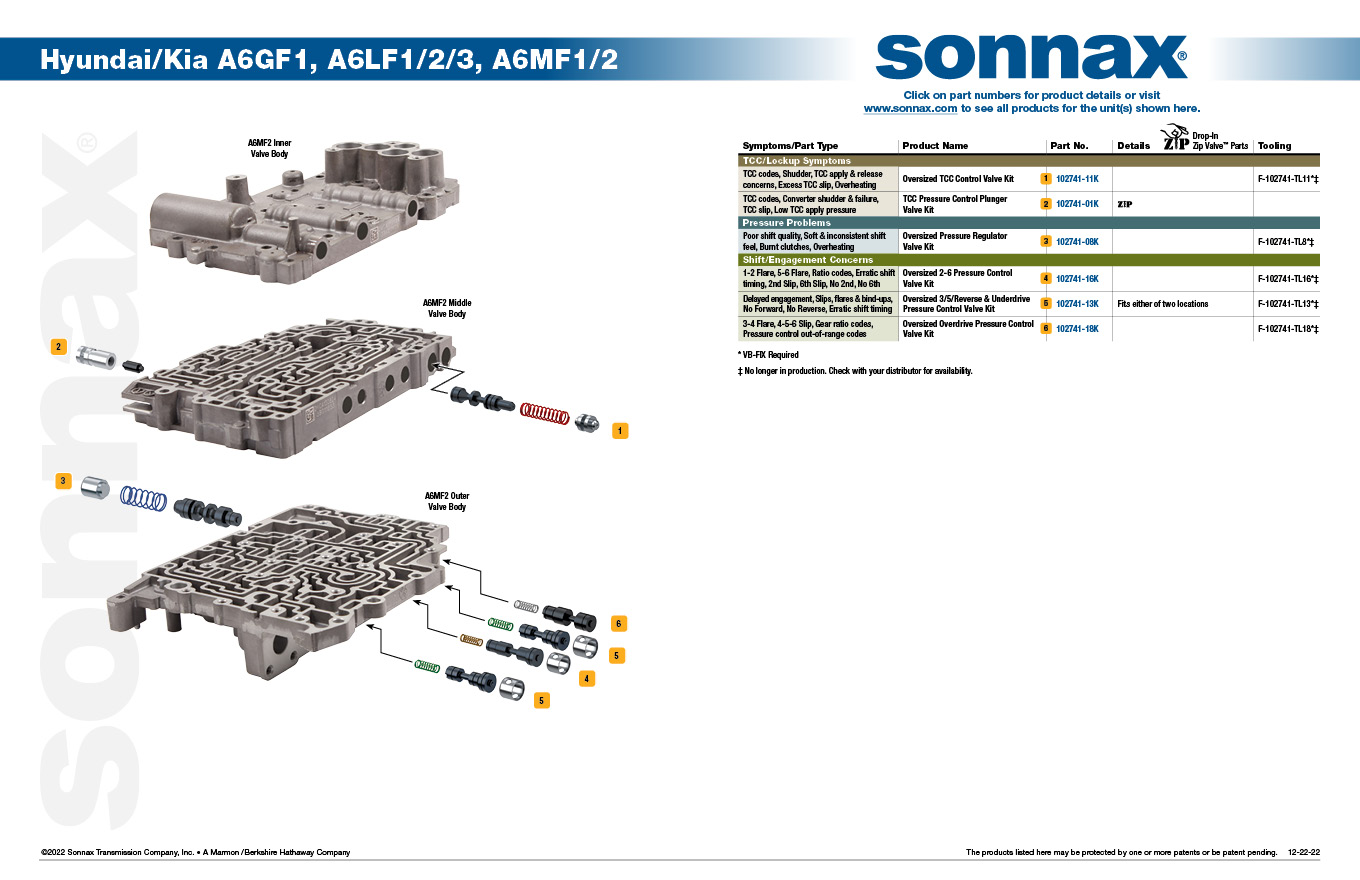

The TCC pressure control plunger valve and sleeve assembly act to increase pressure to the TCC switch valve. When this control assembly wears, the oil driving the plunger valve and inboard control valve leaks to exhaust, resulting in decreased pressure to switch valve. This pressure deterioration can cause lockup apply issues, TCC codes and premature failure of the torque converter. Installation of Sonnax TCC pressure control plunger valve kit 102741-01K will arrest these leaks and reestablish appropriate TCC pressure control.

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

September 30, 2005

Gregg Nader

Excessive wear can often be visually identified by shiny patches on the inside diameter of sleeve. Wear can also be determined by vacuum testing, done through feed hole in OE sleeve. Using a small tip (available in Sonnax vacuum test stand kit VACTEST-01K) attached to the line, apply vacuum to one of the feed holes while covering the hole on the opposite side. Be certain OE plunger valve is installed in sleeve while checking.

If sleeve fails to hold at least 18 in-Hg, install this kit.