November 24, 2015

Symptoms:

- Delayed Reverse

- 2-3 Flare

- 4-5 Flare

- Ratio codes

- 3rd Slip

- 5th Slip

- Direct clutch burned

- Bind-up

- Reverse slip

Cause:

Persistent oscillation of the direct clutch regulator valve causes bore wear that prevents proper hydraulic control of direct clutches.Correction:

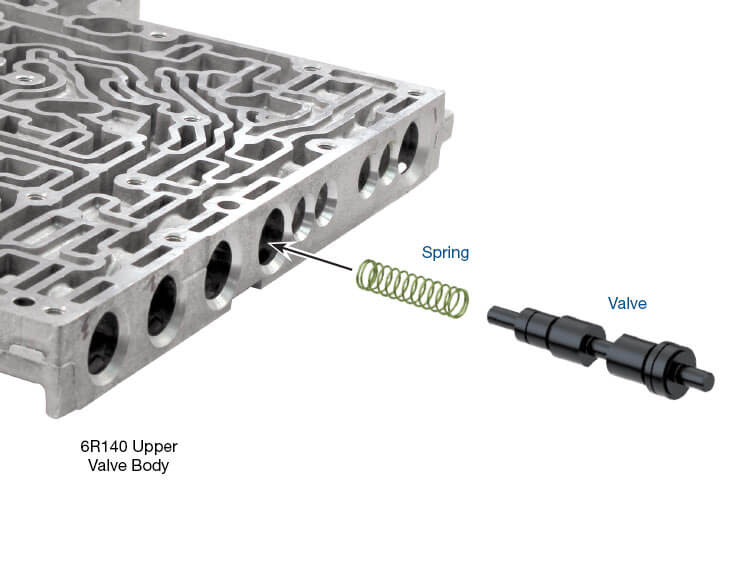

Recover hydraulic control and renew shift performance by reconditioning the bore and installing Sonnax oversized direct clutch regulator valve kit.6R140

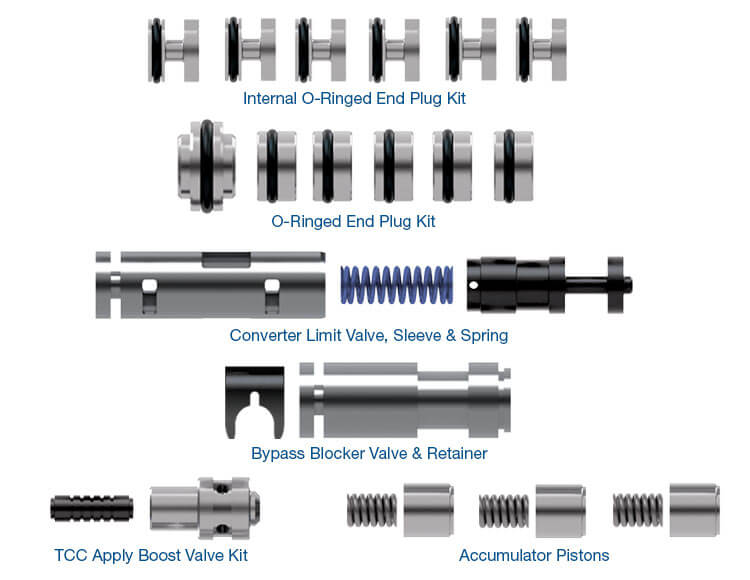

Oversized Direct Clutch Regulator Valve Kit

Part No. 126740-11K

-

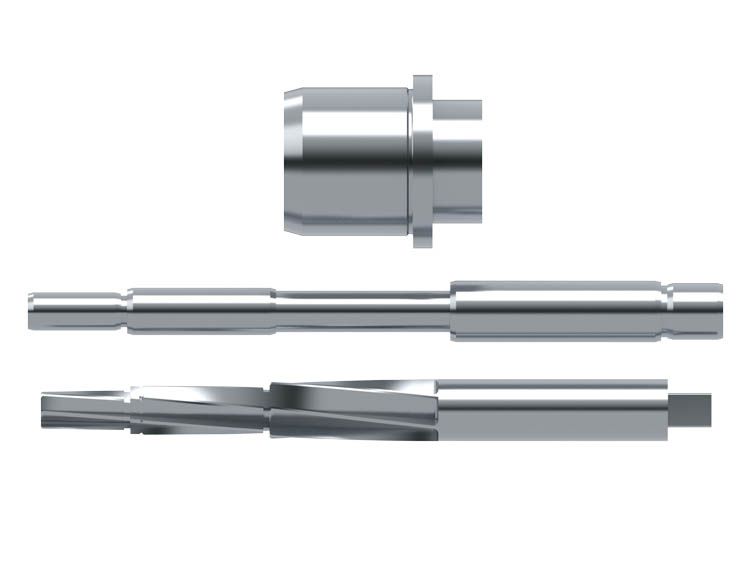

Tooling:

- F-126740-TL11

- VB-FIX

You need this if... View Instructions Find a Distributor

Direct clutches in Ford 6R140 transmissions are applied in 3rd, 5th and Reverse Gears in conjunction with other clutch packs. As the direct clutch regulator valve oscillates and strokes over time, bore deterioration results, allowing critical pressure to exhaust and preventing proper hydraulic control of the direct clutch. This can cause flares, slipping, erratic clutch apply timing, ratio codes, bind-ups and burnt direct clutches.

Reconditioning the bore and installing Sonnax oversized direct clutch regulator valve kit 126740-11K restores normal shift operation by restoring the hydraulic integrity of the direct clutch circuit.

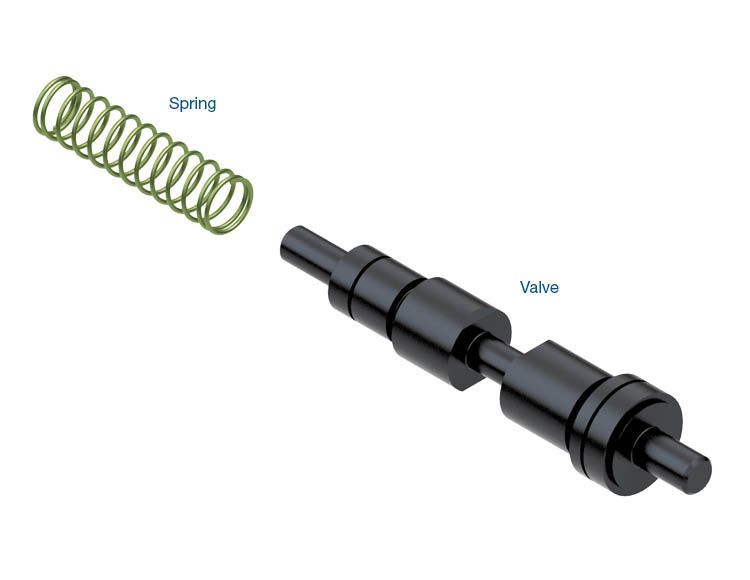

- Annular grooves help center valve in bore to reduce future side-load wear

- Hardcoat anodized aluminum valve combats premature wear

- Valve

- Spring

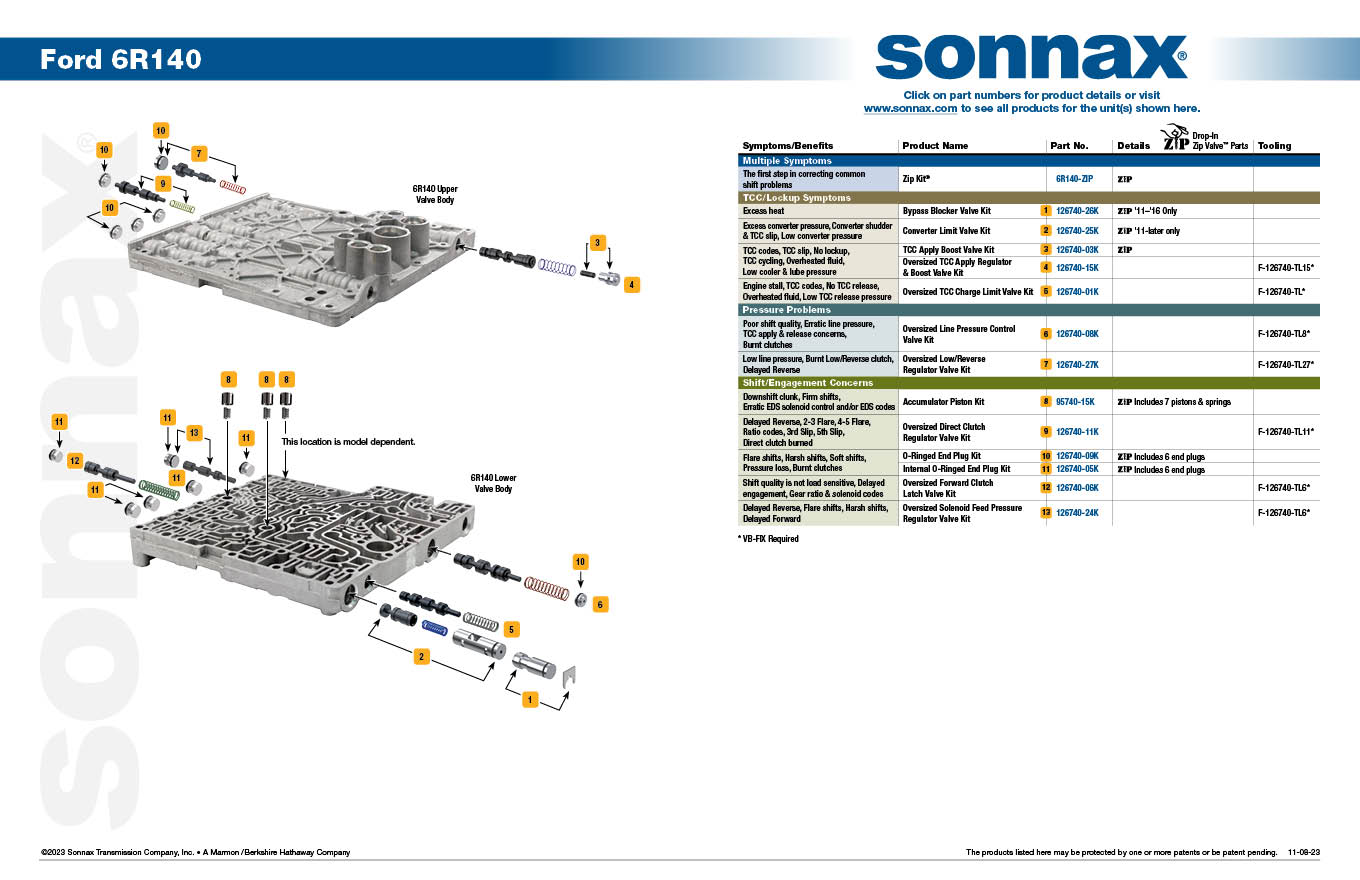

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

Ford 6R140 Valve Body Layout

August 15, 2022

Troubleshooting Ford 6R80 & 6R140 Timing-Related Shift Issues

Jim Dial

September 16, 2022

Troubleshooting Ford 6R80 & 6R140 2-3 Shift Quality Issues

Jim Dial

You need this if...

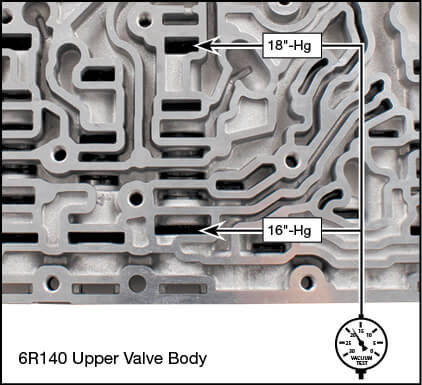

Vacuum testing at the port(s) indicated fails to hold the recommended minimum in-Hg, or if wear is visually detected.