April 05, 2016

The Prescription for Optimum Pressure

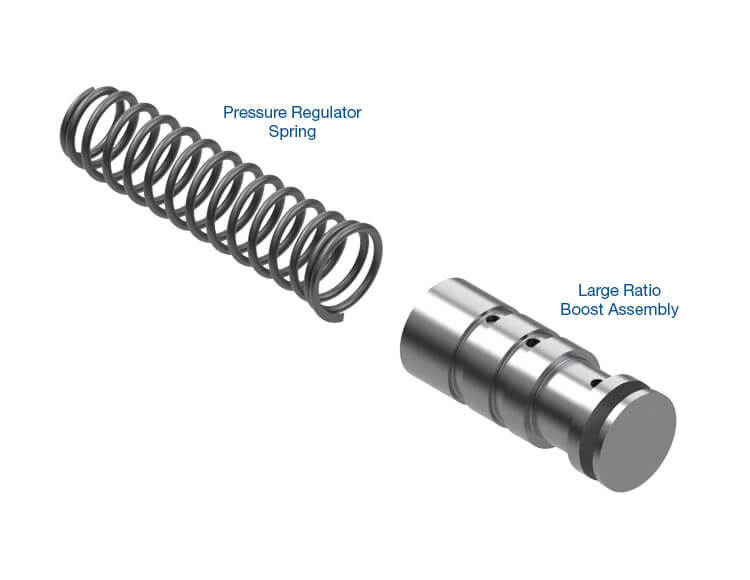

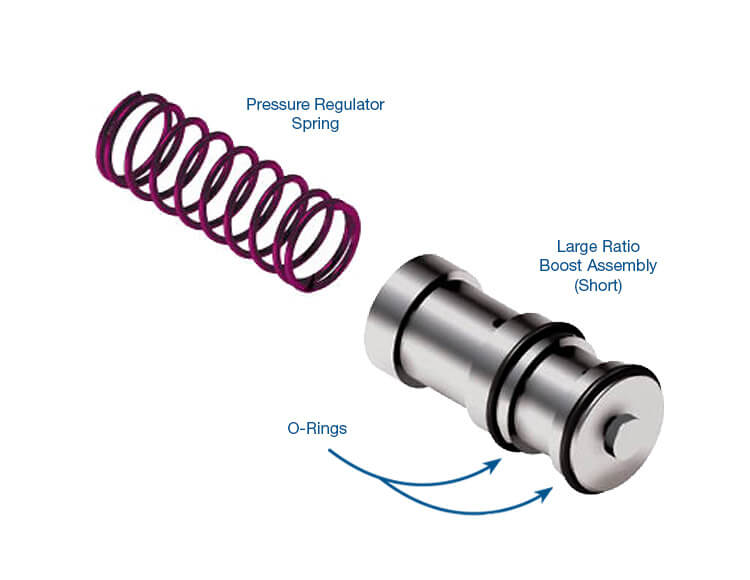

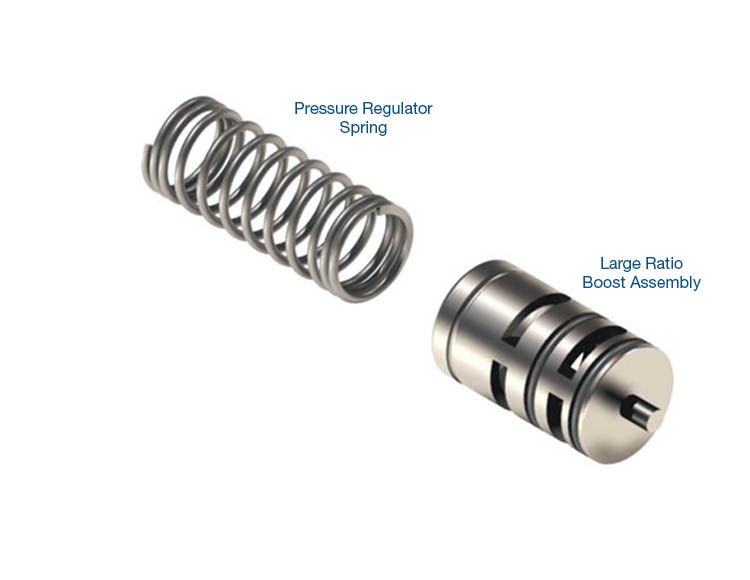

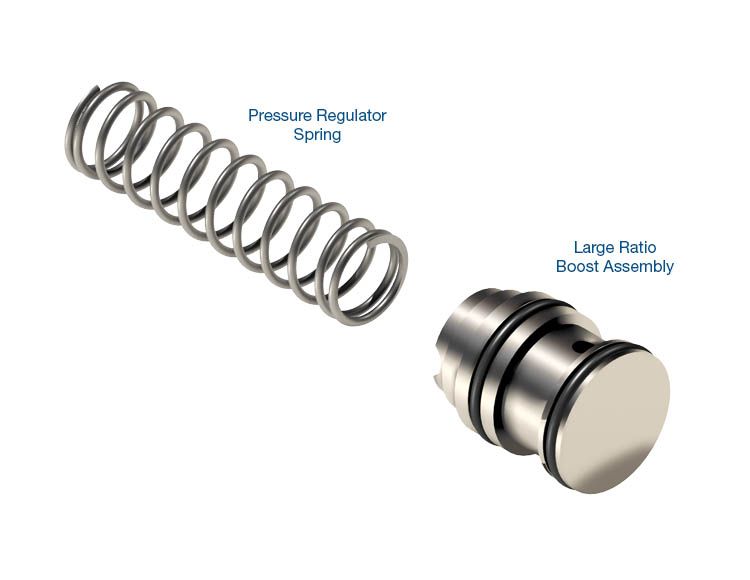

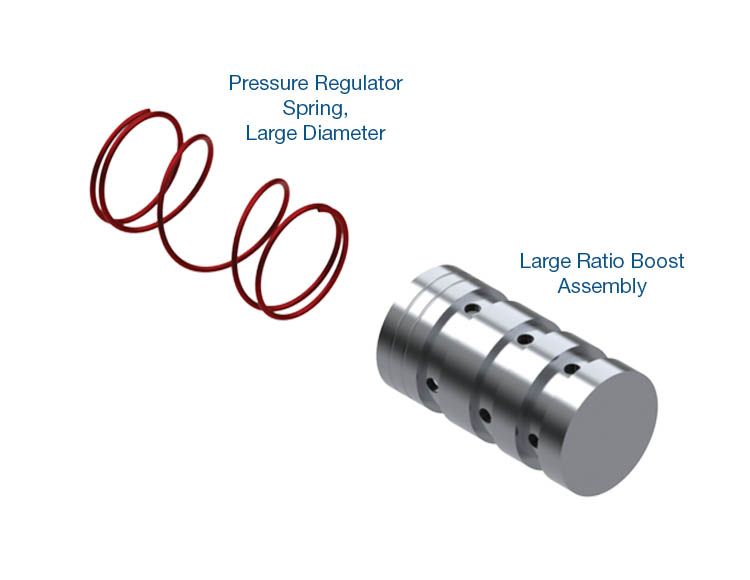

Sometimes a little more pressure is just what the doctor ordered. Raising line pressure is the most basic change you can make to your transmission. It can breath new life into old transmissions with sagging pressure regulator springs, or provide extra clutch and band apply pressure in hard-working units. Raising line pressure is typically done by using a stronger pressure regulator spring, installing a larger boost valve or doing both.

Sonnax offers several products which raise line pressure and, more importantly, vary the rate of pressure increase. Our lineup of pressure regulator springs and larger ratio boost valves is continuously growing, providing more and more options when you want to tweak a unit above stock pressures.

Stronger Springs vs. Larger Boost Valves

A stronger spring and larger boost valve will both increase pressure, just not in the same way, so it's important to understand the differences before making any changes.

Stronger springs have a "linear" effect on pressure. This means you get the same amount of pressure increase at the low and high ends of the pressure range ('A' on Figure 1). While a stronger pressure regulator spring will raise line pressure, there is a limit to how much you can get away with before troubles surface. A significant pressure increase that tightens upshifts under heavy load can be too much of an increase when shifting into reverse in the garage. This increase also puts extra load on the pump at idle and can result in the TCC clutch dragging due to reduced cooler flow.

|

Larger boost valves have a "progressive" effect on pressure: they change the rate of pressure increase. Using larger boost valves ('B' on Figure 1), it's possible to have a very small pressure increase at the low end of the pressure range and a far greater increase at the high end. This creates an ideal situation: smooth engagements and lower load on the pump at idle, plus a greater increase in pressure as the transmission is worked harder. The significance of changing the rate of pressure increase with larger valves – rather than simply increasing pressure by the same amount with springs – is that higher pressure is created when it is needed most.

Sonnax hydraulic line pressure booster kits contain pressure regulator springs and boost valves designed to work together. Our pressure regulator springs are about 10% stronger than the OEM springs, but far more conservative than other aftermarket "kit" springs. When the Sonnax springs and larger ratio boost valves are combined, you get the best of both worlds: a modest pressure increase at the low end, with a high end pressure that is equal to or greater than that of "kit" springs. Driving a vehicle with this combination of Sonnax parts will result in normal engagements, normal light throttle shifts and smooth coast-down shifts. When pushed harder or driven aggressively, pressure increase becomes progressively greater, ensuring that shifts are not too soft. You may not need this for great-grandma's grocery-getter, but for most other vehicles, Sonnax hydraulic line pressure booster kits will add just the right touch to make sure the pressure is there when needed.

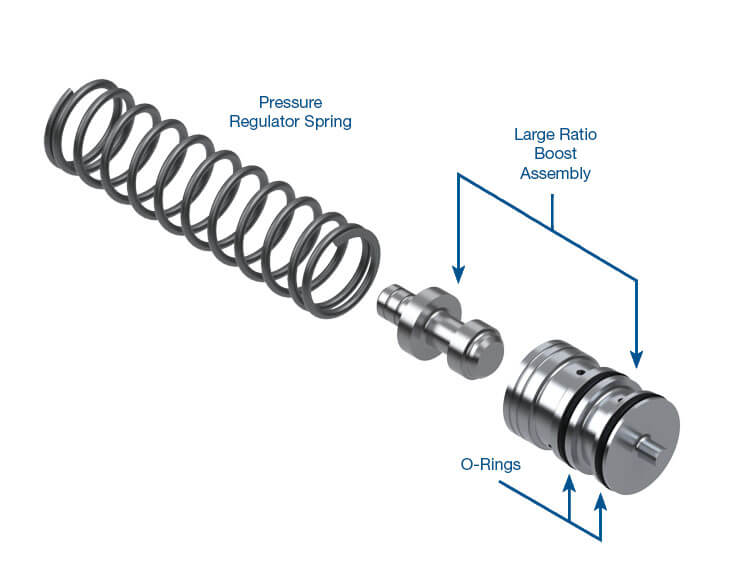

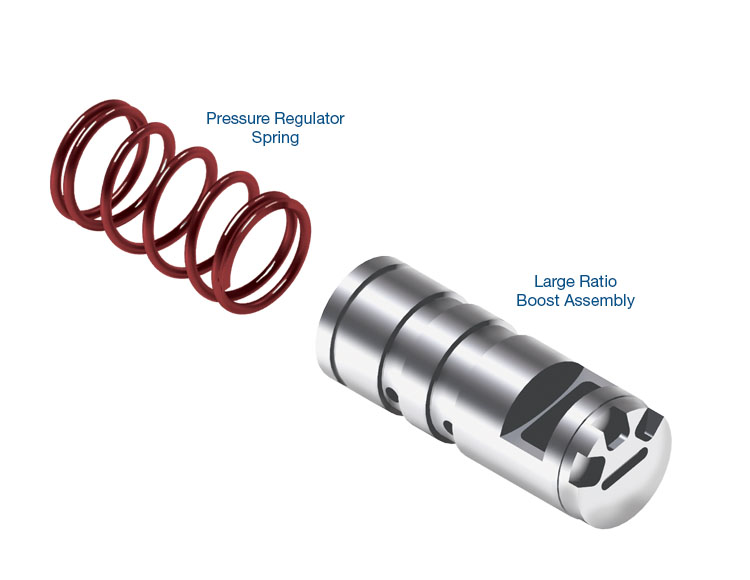

How Does a Boost Valve Work?

The pressure regulator spring sets the base line pressure. The job of the boost valve is to help the pressure regulator spring increase line pressure as needed. In typical applications, oil pressure from the EPC solenoid, vacuum modulator or TV valve is directed to the end of the boost valve ('A' on Figure 2). As this oil pressure changes, so does the force assisting the pressure regulator spring, causing line pressure to increase. This variable pressure allows higher pressure under loads and during acceleration when it is needed most. When the diameter or reaction area on the boost valve is made larger, more force will be created to help the pressure regulator spring.

Many boost valves feature an additional reaction area where reverse oil reacts to increase pressure in reverse ('B' on Figure 2). Sonnax boost valves are designed to get the right combination of pressures through tuning these two reaction areas. The larger-ratio Sonnax 4L80-E valve in booster kit 4L80E-LB1 is an example of "tuning out" some of the reverse pressure so that the majority of the pressure increase is in the forward ranges.

Electronic Line Boosters

Automakers possess many different systems to regulate and vary line pressure. The Chrysler 45RFE, 545RFE and 68RFE units have a unique, full-range pressure transducer and real-time adaptive closed-loop pressure control system. Because of this, it is not possible to raise pressure in an RFE the same way you would in other transmissions. Installing a stronger pressure regulator spring or larger boost valve will not be effective because the RFE control module will simply adapt and return pressure to OE specification. An electrical booster option is necessary to raise pressure on an RFE.

Sonnax line pressure booster kit RFE-LB1 is an improved design over a simple resistor circuit. Featuring an integrated chip (IC) circuit and a stronger pressure regulator spring, this kit delivers 10 psi increase at lower pressure range and 25 psi increase at higher pressure ranges. To find out more about how the kit works and what results you can expect, see Achieving a Progressive Pressure Boost in RFEs.

Sonnax line pressure booster kit RFE-LB1 is an improved design over a simple resistor circuit. Featuring an integrated chip (IC) circuit and a stronger pressure regulator spring, this kit delivers 10 psi increase at lower pressure range and 25 psi increase at higher pressure ranges. To find out more about how the kit works and what results you can expect, see Achieving a Progressive Pressure Boost in RFEs.

Learn More

Related Units

Related Parts

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.