August 18, 2017

A Universal Solution for Reaming Valve Bodies

Scott Jackson

Reaming valve body bores back to OEM quality specifications is no easy task. At the OEM level, multi-million-dollar machining centers are carefully designed to do just that. These machines are uniquely designed for each and every application. Although hand reaming to the same tolerances can be very difficult, it is not impossible. For the last eight years Sonnax has led the way in the refurbishing of valve body bores using custom-designed reamers and replacement valves and sleeves.

The development of these tool kits has been an evolutionary process, with many hurdles to overcome. At Sonnax we constantly strive to make our tool kits user-friendly with the ability to consistently ream valve body bores back to within OEM specifications with regard to size, roundness and surface finish. Now, with our valve body reaming fixture, you can refurbish those valve body bores more easily and with more consistent results.

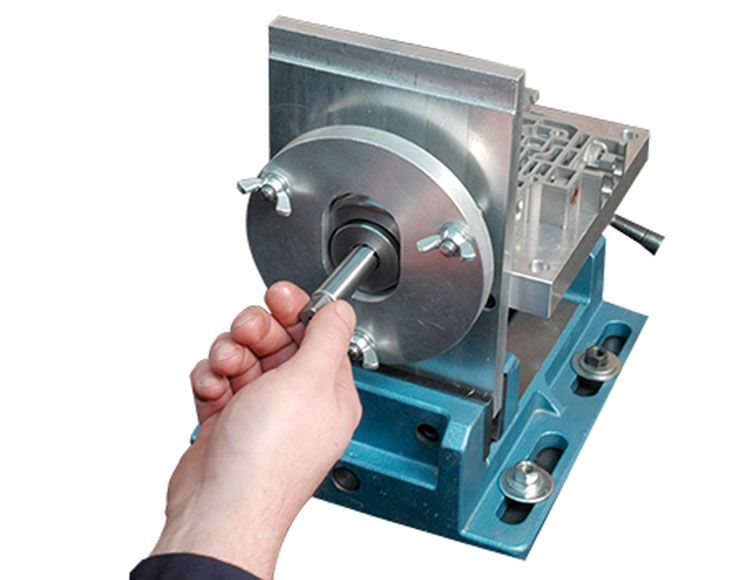

Proper alignment starts out with making sure that any solenoid or end plug bore being used to guide the reamer is on the same centerline with the bore that is going to be reamed. Since proper alignment is so crucial to reamer performance, the new Sonnax valve body reaming fixture VB-FIX allows the reamer to be precisely aligned with the bore that is going to be reamed.

The system uses an alignment pin that fits into the OE bore. The other end of the pin fits into the reamer guide of the valve body fixture. The reamer guide can be moved up and down and can also swivel to take into account any angular misalignment. Once this pin slides freely within both the valve bore and the reamer guide, the reamer guide is clamped in position. Now the valve bore and reamer guide are lined up and concentric to each other. The guide pin is removed and replaced with a reamer.

|

|

Now we have a reamer that is lined up with the bore it is going to ream, the first step in the process.

Once the reamer is lined up, it is very important to keep it tracking straight. This is the most difficult aspect of the job, but our valve body fixture makes it much easier to keep the reamer on the right path. With minor modifications, this fixture will work on many different kinds of valve bodies, and takes out much of the guesswork involved. We know some rebuilders are reluctant to tackle reaming, but the fixture makes it much easier to ream out worn valve bodies while ensuring consistent results, time after time, in a multitude of units.

In fact, the valve body reaming fixture will allow rebuilders to ream valve bodies they did not have the ability to do before. Some valve bodies could not be refurbished because of the inherent difficulty in getting the centerline of the bore concentric with the reamer centerline. The valve body fixture solves this problem. As the industry comes up with new valve body designs, this fixture will become even more useful.

This fixture has been tested and approved by the TASC Force® (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians. The fixture is made from wear-resistant materials, does not require maintenance, and will make it possible to refurbish a multitude of valve bodies to OEM specifications for size, roundness and smoothness and save rebuilders thousands of dollars in valve body replacement costs.

Scott Jackson is the director engineering and a member of the Sonnax TASC Force® (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries, Inc. technicians.

Learn More

Related Parts

Required

Recommended

Valve Body Reaming Fixture VB-FIX

-

Helps cure:

- Some worn valve & pump bodies cannot be salvaged

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.