The 700-R4/4L60-E family of transmissions is the most popular performance platform in the world, thanks in large part to Sonnax components that allow them to run reliably at extreme power levels. Whether you’re starting from scratch with a heavy duty/performance build or optimizing a seasoned racing vehicle, the following key areas MUST be addressed to realize the full potential of these units:

Hunt Down Unstable Pressure, the Real Pump Killer

When running at higher average pressures, the whole hydraulic system MUST be in top condition to minimize the risk to the pump vane rings. Pressure pulsation from poor PR valve control is the real danger, and a sure sign of this problem is gauge needle-bounce when testing line pressure.

Stabilizing pressure starts with precise valve-to-bore clearances (PR valve bore wear is common in 4L60/E units) and a quality, leak-free boost valve. It’s also essential to feed the boost valve with a properly working (clean) EPC solenoid and steady AFL pressure to the EPC solenoid.

Don’t Get Burned When Expanding 3-4 Clutch Capacity

Expand Clutch Capacity the Smart Way

Guarding against 3-4 clutch failure has traditionally meant working within the limited space of the OE input housing. Squeezing in more frictions requires installing a thinner backing plate with thinner clutches and steels, BUT:

- Adding friction surfaces reduces the amount of steel

- Steel in the clutch pack helps dissipate heat

- Without enough steel, heat builds up and clutches burn

Adding more, thinner plates increases static holding capacity by sacrificing engaging capacity. Durability suffers in higher-load applications where more energy goes into the clutch during the shift. The ONLY way to expand clutch capacity without sacrificing steel mass is by replacing the OE input housing with the patented

Sonnax Smart-Tech® housing. Its custom design holds a physically larger clutch pack to eliminate 3-4 clutch burnup while also guarding against other common problems.

Fix the Flex

The weak OE backing plate flexes during clutch apply, allowing heat to build up unevenly within the clutch pack’s limited space. Burnup is the common result. Stop the flex and you stop 3-4 clutch failure. The Sonnax Smart-Tech housing’s apply and backing plates surround a larger clutch pack area to keep the clutches parallel and maximize protection against overheating.

Watch this video to see the OE flex in action and learn how the Smart-Tech housing will help you get the most out of your favorite clutches.

Take Care of the Servo Band

Switching to a wider band (Sonnax [red band 77700-01] or [Kevlar® band 777000-01K]) is an ideal capacity/durability upgrade, but NEVER install a wider band on a used drum. The old band will have compressed the drum and created a subtle dish on its surface. When used with a wider band, this dish leads to slipping in 2nd gear, glazing and burning, and will eventually throw off the band adjustment.

Always check band/pin adjustment to prevent band release problems. Sonnax servo kits include instructions for setting servo travel between .075" and .125" using a dial indicator. Never shim the servo, as this moves the piston deeper into the bore where it’s more prone to bottoming out and causing band failure.

This

Sonnax tech article on adjusting shift feel in performance builds breaks down OE and aftermarket options for second gear servos.

Stop 3rd Accumulator Checkball Leakage

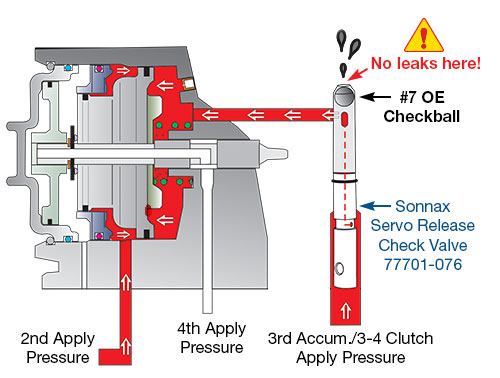

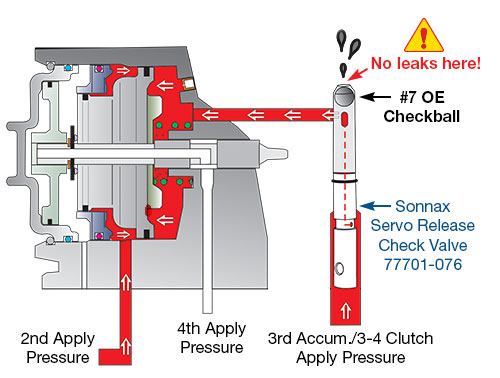

It’s crucial to prevent even minor leaks in the 3rd accumulator checkball assembly, as these are directly related to band and 3-4 clutch failure.

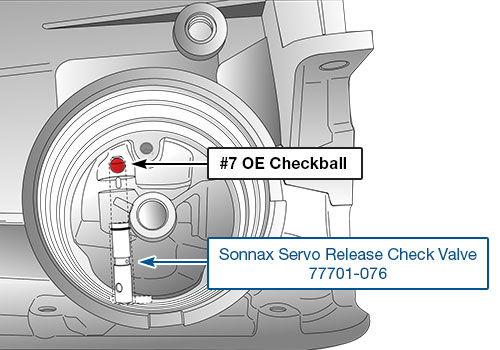

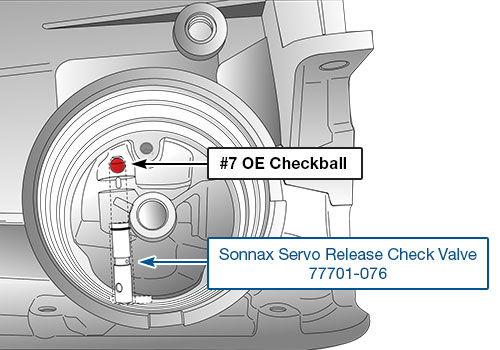

Vacuum testing the #7 checkball (located in the servo area of the case as shown in

Figure 1) with Sonnax [vacuum test stand kit [VACTEST-01K is one quick and reliable way to check for leaks. Read more about recommended testing options in

this Sonnax tech article.

Figure 1: 4L60-E Case Servo Area | Figure 2: 2-4 Servo Assembly Cross Section |

|---|

|  |

Note: Don’t confuse the OE checkball with the one found in Sonnax [servo release check valve kit 77701-076]. Although they look similar, they have completely different functions. The Sonnax kit is a unique solution that combines an orifice with a ball check valve to tune 2-3 shifts, but it MUST be used with a properly functioning OE 3rd accumulator checkball assembly.

Damage to the band, input/output shafts, sprag, etc. can be reduced by properly cushioning the large ratio change on the 1-2 shift:

- Never use a 1-2 servo that eliminates the cushion spring

- Never reduce the 1-2 accumulator piston stroke

- Never leave out the 1-2 checkball

- Never over-drill the 1-2 feed hole

Reduce ratio change by converting 1st Gear from 3.06 to 2.84 with Sonnax input carrier kit

77284-K, a great way to gain a better performing, more durable transmission. The one-of-a-kind Sonnax gear set improves overall launch in powerful applications, plus reduces stress on band and clutches on the shifts. The chart below shows how changing to the 2.84 gear set offers benefits go far beyond a 1st Gear ratio change.

1. There is an obvious change to the 1st Gear ratio: 3.06 to 2.84. This reduces the overall ratio ‘spread’ from 1st Gear to 4th Gear, making a close-ratio

transmission compared to the OE ratios being a wide-ratio spread. This change mostly affects the Starting Line Ratio (SLR) which is calculated by combining the transmission ratio with rear axle final drive ratio and then tire radius. The reduced torque multiplication (from 3.06 to 2.84) also reduces the torque loads on some transmission components.

2. There is a less-obvious, but still important, change in the ratio drop BETWEEN gears. With less ratio drop between gears, there is less work required of the clutches and band to make the ratio change happen. A smaller ratio drop also reduces the shock loads on related hard parts. At both the 1-2 shift and the 2-3 shifts, the Sonnax input carrier delivers a reduced ratio drop. From 3rd Gear on, the OE and Sonnax gear ratios are the same.

Pursue Input Sprag Perfection

You don’t move when the input sprag fails, a critical link often overlooked during transmission upgrades.

- Install a new sprag assembly that includes new inner/outer races. Used races may be worn or manufactured out of spec.

- Easily strengthen and reinforce the sprag by installing Sonnax heavy duty 2-3 shift valve 77754-41.

- Clean fluid is essential for maximum sprag durability. Make sure the transmission pan has a drain plug, and change the fluid often to prevent micron-sized debris from undermining sprag engagement. Never leave magnets out of the pan. In fact, adding EXTRA magnets is a good idea, as they collect the hardest of contaminates most likely to effect the critical EPC solenoid.

Help the Rear Ring Survive by Moving Up to Five Pinions

Increasing the number of planet pinions from four to five distributes load more evenly on the sun gear and around the ring gear. At high torque, this reduces stress/flexing of the ring gear and improves durability.

Control Valve Body Bleeding

The foundation of a good unit is a tight, leak-free valve body that prevents pressure loss, conserves pump volume, keeps pressure stable and reduces fluid foaming in the pan area. Since bore wear is common in the 4L60/E, ALL circuits should be vacuum tested to identify leaks and some repairs may require reaming.

Free Sonnax vacuum test guides show you the locations to test, identify common problems and recommend the right Sonnax parts for repairs.

The valve body shown below includes repairs and improvements that typical of a 4L60/E performance build with some mileage and wear. Or, save time and money with a

quality rebuilt valve body from Sonnax. Each unit is completely refurbished with Sonnax parts, electronically and hydraulically tested, ready to bolt-up as-is or upgrade with your favorite performance mods.

Recommended Valve Body Repairs/Upgrades| ID | Sonnax Component |

|

|---|

| C | Heavy Duty 2-3 Shift Valve | 77754-41 |

| H | Actuator Feed Limit Valve Kit Reaming Required | 77754-09K |

| E | 3-4 Relay O-Ringed End Plug Kit | 77964-08K |

| B | Forward & Reverse Abuse Bore Plug | 77754-21 |

| A | Pinless Forward Accumulator Piston Kit* | In Performance Pack HP-4L60E-01 |

| F | TCC Regulator & Isolator Valve Kit Reaming Required | 77754-04K |

| G | TCC Pressure Limiter Spring** | In Performance Pack HP-4L60E-01 |

| D | 1-2 Accumulator Valve Shim | In Performance Pack HP-4L60E-01 |

*Also available separately under Part No. 77987-01K.

**Valve also included in Performance Pack HP-4L60E-01.

Stabilize Transmission Pressure with a Better Oil Pan

The best deep pan to use is an aftermarket model with a filter extension to place the filter lower into the oil sump. It helps prevent air ingestion during hard acceleration, which can destabilize transmission pressure and lead to slipping.

Optimize Computer Programming & Tuning with Care

No matter how well-built the unit, poor computer programming will quickly kill the transmission. It’s vital to be informed about the many modification options available and how they affect performance and durability. Here are a few examples of classic programming pitfalls:

Pressure Control Optimization

Setting incorrect parameters allows line pressure to drop “off the mapping table” to a minimum range when maximum pressure is required. It’s a well-intended tuning mistake that can lead to clutch-roasting pressure drops. Best practice is to always test drive a fresh installation with pressure gauge installed to verify:

- Base pressure

- Quick pressure rise under load

- Stable max pressures

“Torque Management” Mods

This feature often is completely disabled, even though leaving a little “on” will help maximize driveline durability without slowing the vehicle. Figuring out the best balance requires tuning experience and a solid understanding of a particular vehicle’s setup.

Continuous Slip (EC3) TCC Control

Since higher-stall aftermarket converters aren’t designed for continuous slip, it might seem reasonable to eliminate this function. Simple on-off operation can be excessively harsh, though, especially when the converter is damperless. A better programming option is disabling the EC3 continuous slip, while keeping the pulse-width modulated (PWM) TCC apply so that the converter clutch comes on in a ramped, controlled manner. Learn more about ways to modify TCC apply in the valve body in Sonnax tech article “

20 Years Later: What’s New with 4L60-E PWM Modifications.”

Finally…Play it Safe!

Don’t risk throwing products from different manufacturers into the same tranny when there’s no guarantee they’re all going to play nice. Installing Sonnax parts designed to work together is the best and safest way to upgrade any transmission. These

Sonnax build charts are a great place to start when upgrading heavy-duty pickups or performance vehicles. For assistance with product selection or part installation, contact the

Sonnax tech support team.