Defending the Duramax® Diesel Against Allison® 1000 Stator Weakness

Duramax diesel engines can produce an incredible amount of torque, far more than the stock 2006–2010 Allison 1000 converter is designed to handle. This becomes a huge problem when a driver pushes their “performance” truck to actually perform. Parts break, the vehicle is out of commission and you’ve got a converter in the shop that’s going to fail again if you don’t tackle the real problem: an OE stator pushed beyond its limits. You can now easily take on this challenge by installing an enhanced stator assembly from Sonnax - the first and only upgrade to eliminate the crippling stator weakness in these Allison units.

Weak OE Stator + Performance Engine = Disaster

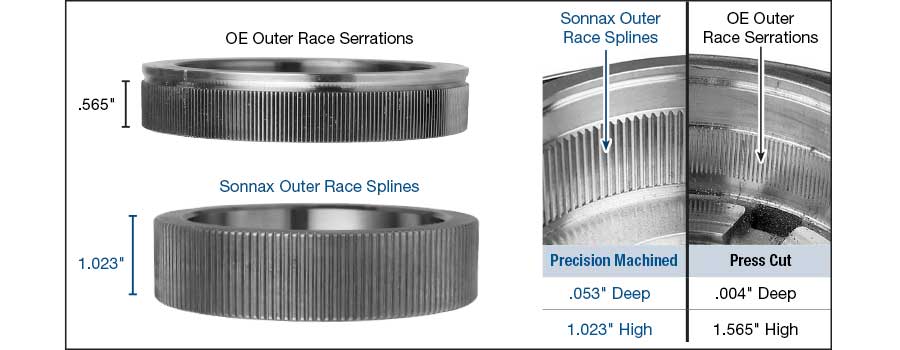

Figure 1 shows the serrations on the inside of the Allison OE stator that engage with the outer stator race. They are shallow - only about .004" deep - and not even etched into the entire length of the race. The form and depth of the serrations are not precision machined. When the race is pressed into the stator, the race splines bite into the aluminum to deepen and form the grooves.

The result of this poor design is hardly any engagement between the stator and outer race. The stator will often break free under too much torque, spinning and damaging the transmission with aluminum debris.

| Figure 1 |

|---|

|

| A stock 2006-2010 Allison 1000 stator. The shallow serrations that engage the race will not hold against the torque produced by high-performing diesel engines. |

Converters with these weak stators are typically found in Chevrolet Silverado, GMC Sierra HD 6.6L Duramax diesels and Allison 1000 transmissions. Although stator engagement was improved in the Allison LCT 1000, 2010-later converters, it was only upgraded for better hold in stock engine applications. In all cases, the real-world performance levels of these powerful vehicles will completely overwhelm an OE stator.

Some rebuilders confronted with converter failure correctly identify the problem as a broken stator and try to repair the damage. One method entails building up the aluminum material in the bore of the stator, boring the inside diameter back to OE specifications and then pressing the OE outer stator race into the pocket of the stator. This is just a repair, though, not a long-term solution. Reusing the OE stator only restores the same poor engagement that caused converter failure in the first place.

Another workaround for this problem involves drilling and pinning the outer stator race and the bore of the stator to ensure it can’t spin under high torque. This technique might be more effective than resurfacing the part, but it involves time, labor, machining and tooling expenses that add to the cost of rebuilding a unit.

Rebuilders can easily eliminate the critical weakness of the Allison converter with Sonnax’s new AL-ST-1K stator kit. The custom stator and outer stator race feature longer and deeper precision- machined splines to hold many times more torque than the OE stator assembly (Figure 2).

| Figure 2 |

|---|

|

The Sonnax kit is a must-have replacement part for failed converters as well as new rebuilds in the two most common Allison converter applications (Figure 3).

| Figure 3 | ||

|---|---|---|

Converter Generation |

TC-211 (Green) 2.01:1 Stall/Torque Ratio |

TC-221 (Black) 1.75:1 Stall/Torque Ratio |

| 1st | 29530318 | 29530317 |

| 2nd | 29538348 | 29538347 |

| 3rd | 29538529 | 29538528 |

| 4th | 29541293 | 29540484 |

| 5th | 29543003 | 29543017 |

| Sonnax stator kit AL-ST-1K will work for the two most common Allison converters. Use this chart to help identify which part numbers should have the weak OE stator assembly replaced. | ||

Related Units

Related Parts

Required

Recommended

Required

Recommended

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.