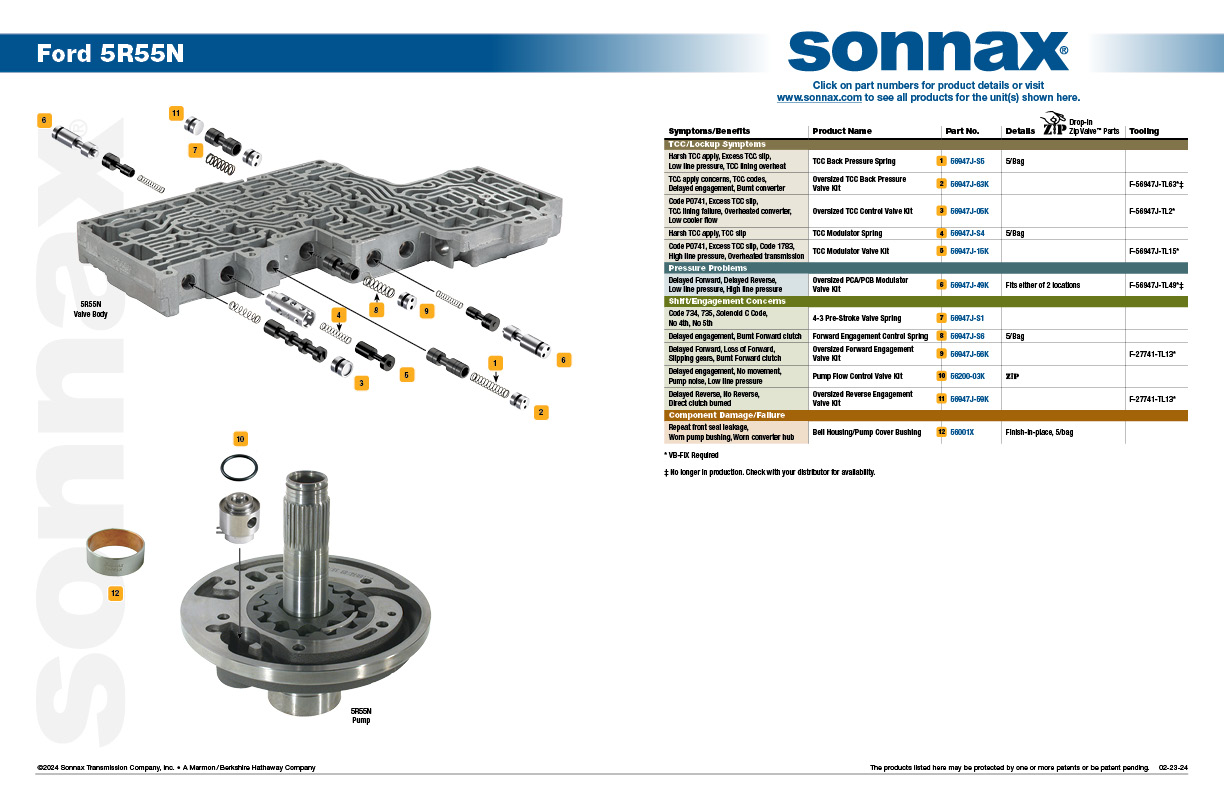

Symptoms:

- Delayed Forward

- Delayed Reverse

- Low line pressure

- High line pressure

- Pressure control out-of-range codes

- Burnt Forward clutch

- Burnt intermediate band

Cause:

Bore wear results in reduced feed pressure to overdrive, intermediate or low/reverse servos or the coast clutch.Correction:

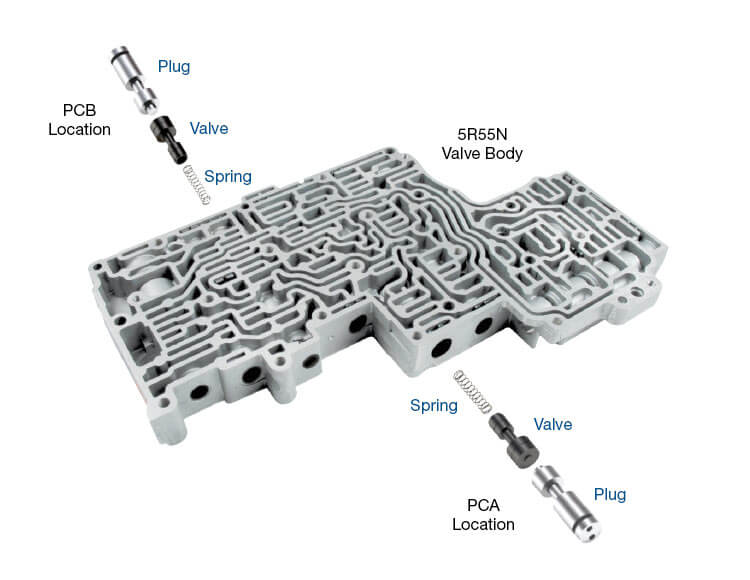

Recondition the bore and install Sonnax oversized PCA/PCB modulator valve kit to restore proper hydraulic function and prevent future leakage. This Sonnax kit works in either modulator valve location.Warning:

Required tool kit F-56947J-TL49 is no longer in production. Check with your distributor for availability.

5R55N

Oversized PCA/PCB Modulator Valve Kit

Part No. 56947J-49K

-

Tooling:

- F-56947J-TL49

- VB-FIX

You need this if... View Instructions Find a Distributor

Ford 5R55N units commonly experience low line pressure and delayed engagements, typically resulting in pressure out-of-range codes, burnt forward clutches or intermediate bands. Bore wear at the VFS1 (PCA) and VFS2 (PCB) locations allows modulated line pressure to exhaust instead of feeding the overdrive, intermediate or low/reverse servos or the coast clutch, causing the complaints and damage. Recondition the bore and install Sonnax oversized PCA/PCB modulator valve kit 56947J-49K to restore hydraulic control and optimum line pressure feed to affected circuits. The Sonnax kit can be used in either location.

- Hardcoat anodized aluminum valve combats premature wear

- Critical valve spools incorporate annular grooves for better hydraulic centering and reduced leakage and wear

- Works in either modulator valve location

- Valve

- Plug

- Spring

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

Ford 5R55N Valve Body Layout

You need this if...

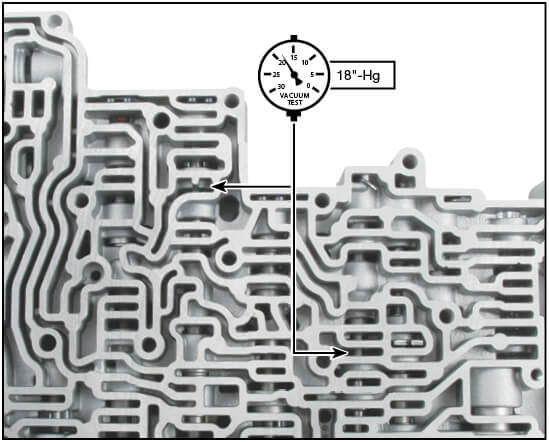

A vacuum at either port indicated fails, or if visual wear is detected at the inboard overlap valve bores.