January 25, 2023

Uncovering the Root Cause of Pressure & Complaints – The Critical Role of Solenoid Modulator & AFL Valves

Maura Stafford

In GM 4T80-E units, the OE actuator feed limit (AFL) valve routes regulated line pressure to the pressure control and shift solenoids. AFL pressure feeds the pressure control solenoid, which regulates the outgoing torque signal pressure. AFL pressure is directed to the shift solenoids to oppose spring force and stroke the shift valves. Constant oscillation of this hardened steel valve causes the cast aluminum bore to wear, reducing the AFL oil pressure, which can cause solenoid and ratio codes, clutch/band failure and harsh shifts. Bore wear can also cause the valve to stick in the exhaust position, resulting in 2nd Gear starts and low line pressure. Sonnax AFL valve kit 72854-01K re-establishes the hydraulic integrity of the circuit by eliminating and preventing wear in the AFL circuit.

January 25, 2023

Maura Stafford

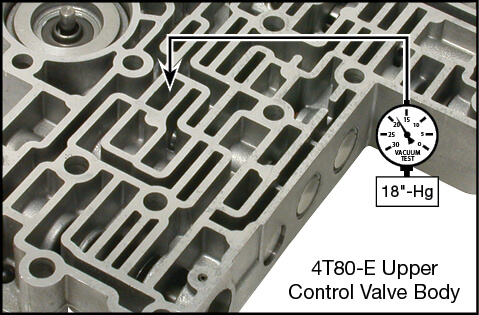

Vacuum testing at the port(s) indicated fails to hold the recommended minimum in-Hg, or if wear is visually detected.