September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

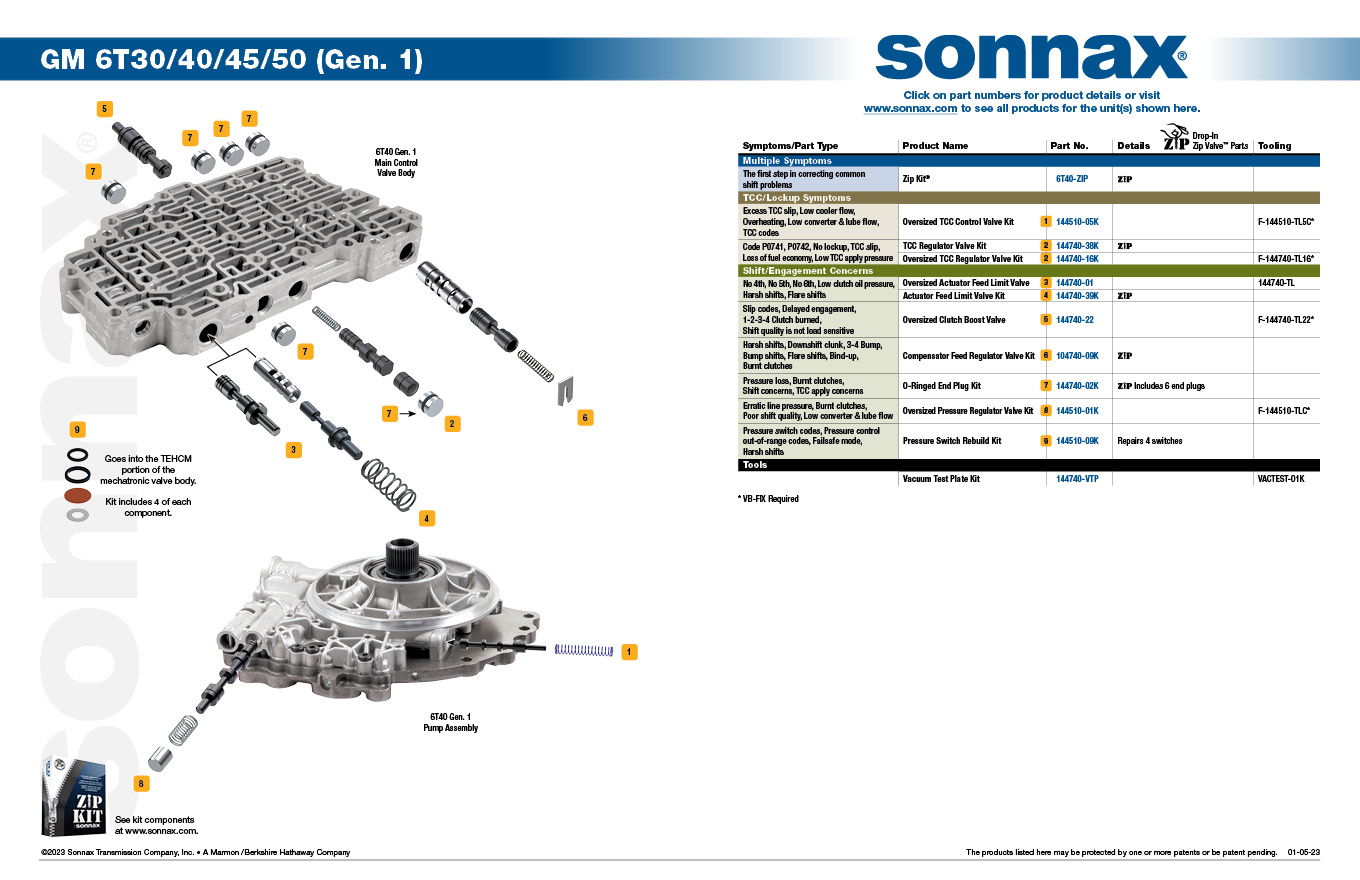

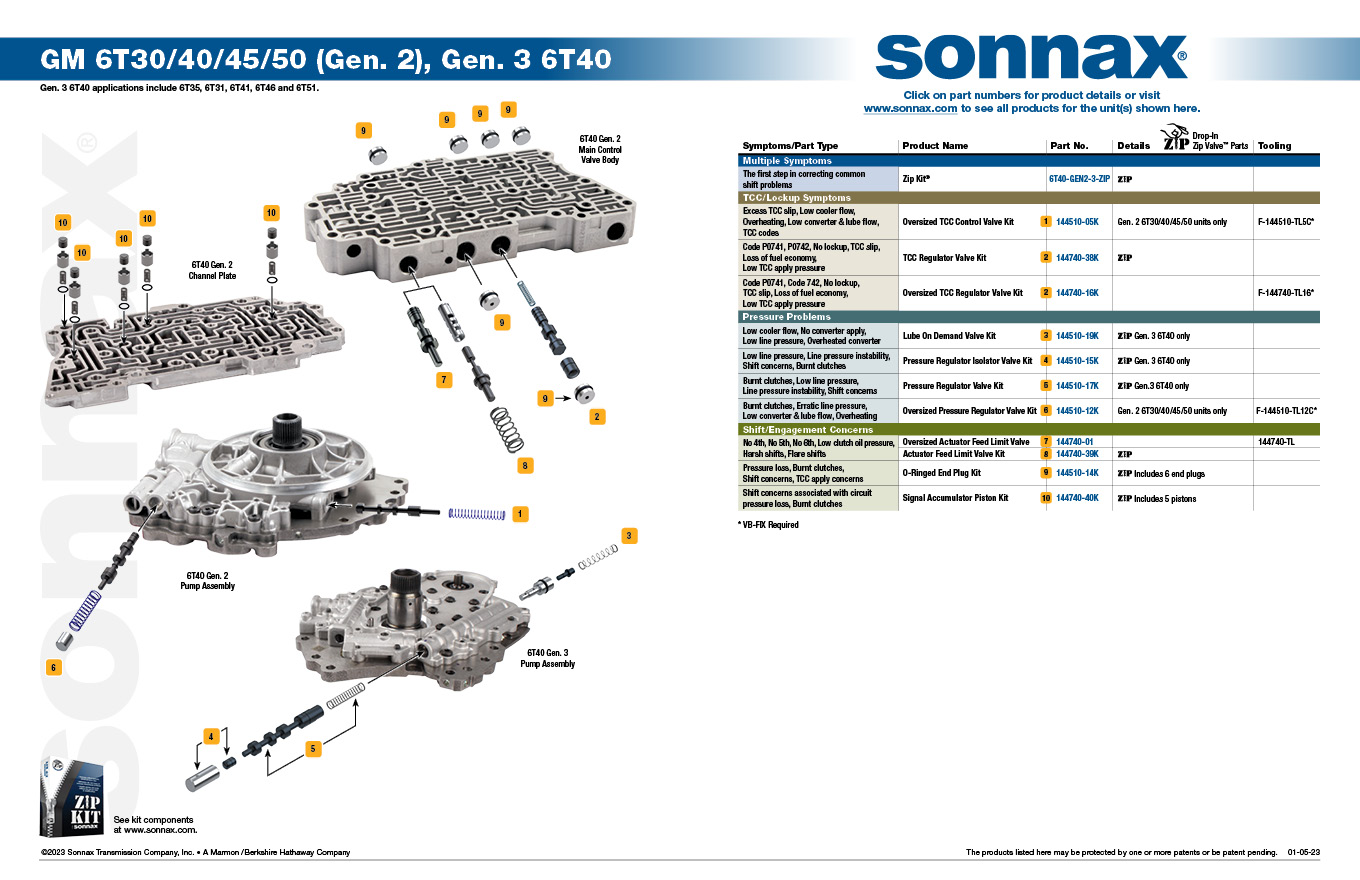

Vehicles equipped with 6T30/40/45/50 (Gen. 1 and 2) and 6T35/31/41/46/51 (Gen. 3 6T40) transmissions can exhibit a number of TCC apply issues caused by bore wear at the TCC regulator valve. Slipping TCC, no TCC apply, fluid overheat and suffering fuel economy are common results of this wear. If the valve becomes stuck in the apply position, harsh TCC apply will be the consequence. If the valve is stuck in the release position, no TCC apply or TCC slip will occur. Installing Sonnax oversized TCC regulator valve kit 144740-16K re-establishes correct valve-to-bore clearances, restoring normal TCC operation.

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

September 30, 2005

Gregg Nader

October 31, 2014

May 25, 2017

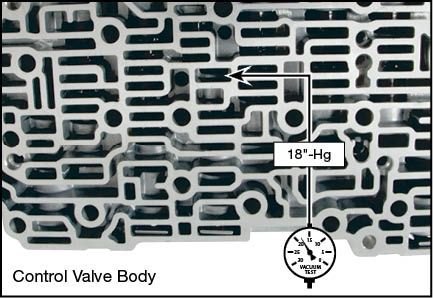

Vacuum testing at the port(s) indicated fails to hold the recommended minimum in-Hg, or if wear is visually detected.