February 26, 2019

Hydraulics Fundamentals Part II: Accumulators & Shift Feel

Maura Stafford

The GM 4L60 and 4L60-E transmissions have been around since  1982, so virtually everybody in the industry is familiar with their designs and how they work. However, one thing that still generates numerous technical calls and confusion is the alphabet soup of different letter codes that are stamped on the accumulator valve, what they mean, and how they affect the transmission. A short review of hydraulic theory and some simple graphs should help bring clarity to these questions and provide guidance on which letter code would be best in various situations.

1982, so virtually everybody in the industry is familiar with their designs and how they work. However, one thing that still generates numerous technical calls and confusion is the alphabet soup of different letter codes that are stamped on the accumulator valve, what they mean, and how they affect the transmission. A short review of hydraulic theory and some simple graphs should help bring clarity to these questions and provide guidance on which letter code would be best in various situations.

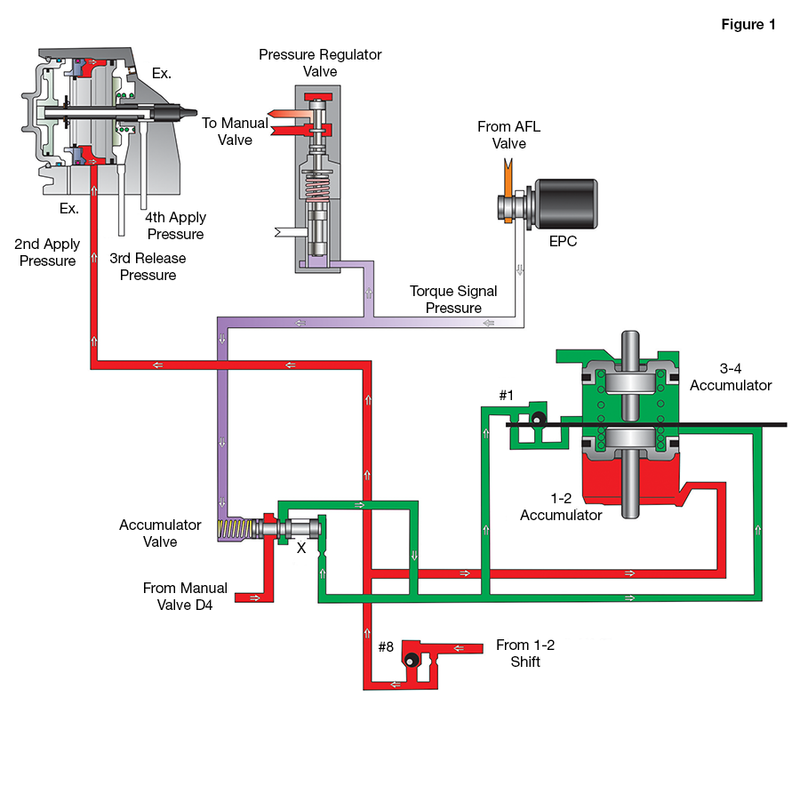

A condensed oil circuit that highlights the 2-4 servo, accumulator valve, 1-2 and 3-4 accumulators is shown in Figure 1. The 2-4 servo is used to apply the 2-4 band in 2nd Gear using 2nd clutch (line) pressure on the 2nd apply piston, and in 4th Gear using 2nd clutch and 4th (line) pressures on the 2nd and 4th apply pistons. There are various sizes of OE and aftermarket servo pistons available, which will allow for greater holding power and reduction of 3-4 clutch and 2-4 band failures.

| Figure 1 – Servo Assembly Cross-Sectional View |

|---|

|

The 1-2 and 3-4 accumulator pistons are responsible for the 1-2 and 3-4 shift feel by providing the hydraulic cushioning of 2nd clutch and 4th fluid pressure and altering the band apply rate. Both pistons use accumulator pressure fed from the accumulator valve to aid the springs in cushioning the band apply rate for a smoother shift. This accumulator pressure is regulated and varies in relation to the engine torque. So in heavier throttle conditions, a greater apply pressure is required and a quicker apply rate results. Light throttle conditions demand lower pressure, and a slower apply rate results.

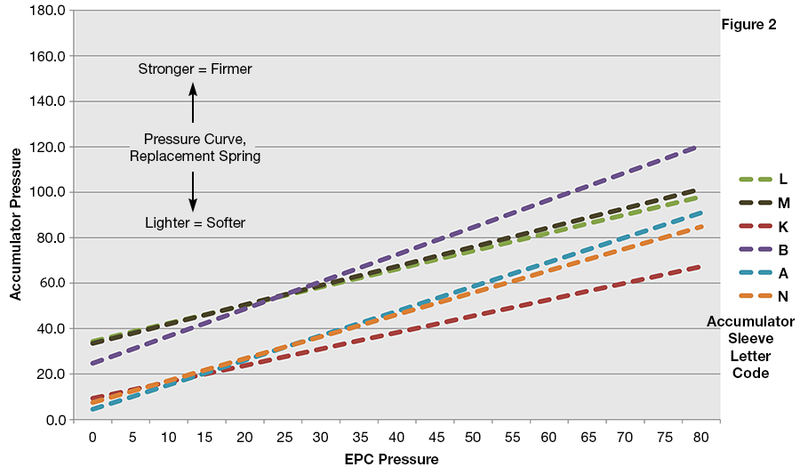

The other influencer on shift feel comes from the differences in the accumulator valve spool sizes and the associated spring, which is what the letter codes on the accumulator sleeve indicate. Therefore, knowing how each of these codes influence accumulator pressure will help in determining if they will make the 1-2 and 3-4 shifts lighter or firmer. The graph in Figure 2 shows the accumulator pressure curves related to EPC/Throttle pressure in 700-R4 or very early 4L60-E applications. Because this accumulator pressure helps to resist the stroking or cushioning effect of the accumulator piston, the pressure curves that are lower (K, N, A) on the graph will allow for a lighter apply rate and shift. The pressure curves that are higher (B, M, L) on the graph will provide a firmer shift. A common practice is to alter the accumulator valve spring during a rebuild, so putting in a spring that’s stronger than the OE will push the curve higher and provide firmer shifts.

| Figure 2 – Accumulator Valve Code Pressure Curves & Spring Replacement Influence |

|---|

|

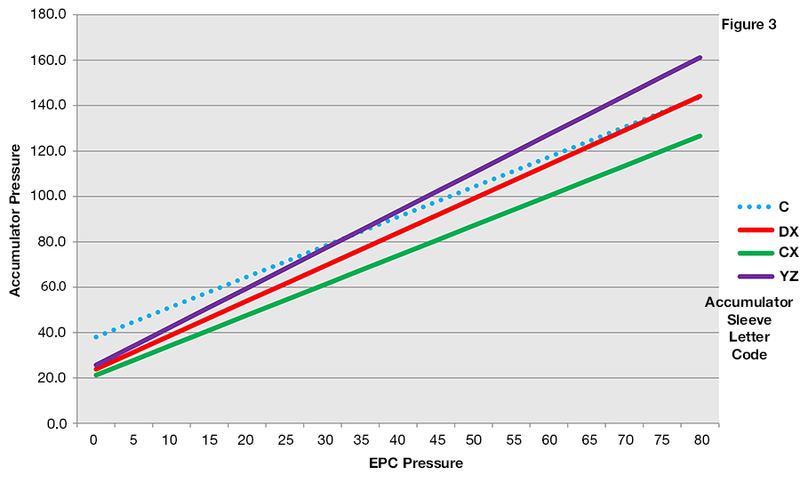

The graph in Figure 3 shows the accumulator pressure curve related to EPC pressure for early (C) and later (YZ, CX, DX) 4L60-E applications. By comparing the firmer 700-R4 codes (B, M, L) with the 4L60-E codes, it is noted that at lighter throttle the overall pressure and shift firmness is relatively equal. However, in heavier throttle conditions, the 4L60-E accumulator valve designs provide a noticeably firmer shift .

| Figure 3 – Later 4L60-E Series Accumulator Valve Pressure Curves |

|---|

|

Choosing the correct accumulator valve code and associated spring for your customer can be as simple as A, B, C when you understand the overall hydraulic theory and relative effect of each code.

Maura Stafford is Sonnax vice president of transmission products. She is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Transmission Company technicians.

February 26, 2019

Maura Stafford

Required

Recommended

Required

Recommended

Required

Recommended

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.