January 22, 2012

Reverse Drum Wear: a 4L80-E True Story

Randall Schroeder

While not as sensitive as some shifting bands, the Reverse band adjustment on a TH400 or 4L80-E transmission is critical, and failure to get it right has tripped up even the best builders. There is nothing worse than getting the transmission installed, putting it in Reverse and then not going anywhere or having no engine braking in Manual Low. The main reason for this is band adjustment/servo travel is not easily checked or adjusted. There are OE tools (J38737/J21370-10) for checking and selective length pins for adjusting travel, however the tools are expensive, hard to locate and difficult to use. Additionally, the OE selective pins have been discontinued. The solution: make your own tool to set pin travel.

Note that Sonnax offers an adjustable rear servo pin kit 34912-01K that allows you to easily set the five longest OE pin lengths in TH400 and '95-earlier 4L80-E units. An added O-ring prevents line pressure leakage, making it an ideal upgrade for both stock and high-performance applications (Figure 1).

| Figure 1 – Sonnax vs. OE Pin |

|---|

|

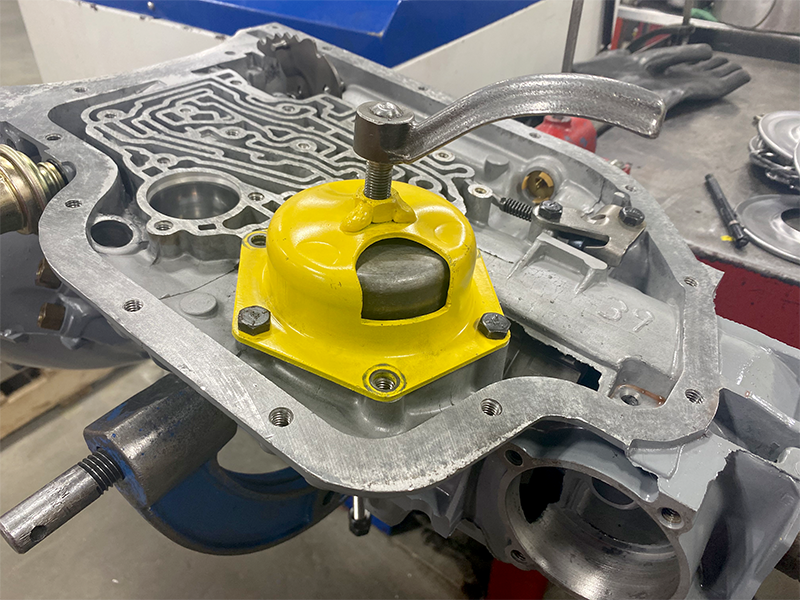

Most likely you have what you need using spare parts lying around the shop. There are three styles of servo covers for these units, but just two are needed for making servo-checking tools: a TH400 and a late 4L80-E, which works for both late and early units (Figure 2). You will need to cut a window in the cover to see the piston. Drill a hole down through the top of the cover so you can tack weld a nut to the top. A 7/16-20 fine thread is preferred, as this makes for a convenient .050" travel per turn. Then, thread the bolt down in until it just makes contact with the piston. You can make yourself a handle to help count your turns or just leave the head of the bolt.

| Figure 2 – Modified Servo Covers for Checking Pin Travel |

|---|

|

If you are using the Sonnax pin, add the appropriate number of small washers to achieve proper length. For assembly directions, refer to instructions for 34912-01K. Once the pin is assembled in the piston, install it in the case with the tool bolted down over it. Tighten the bolt until it is just barely contacting the piston. From here, you have different options for checking travel. Either measure from the top of the cover to the top of the piston and zero your calipers, or measure from the top of the bolt to the cover. Tighten bolt down until the band is seated and check your measurement. The piston should travel .125". You may need to add small washers to achieve this number and may need to repeat this process until you get the proper amount of travel. You can also just count the turns of the bolt. With the 7/16-20 thread, the .125" travel equals 2.5 turns (Figure 3).

| Figure 3 – TH400 Bolted Over Servo Piston |

|---|

|

There is more than one way to determine pin length/servo travel in these units. There are two main things that really matter. One is to make sure the band does not drag on the reaction carrier when released. The second is that the band is gripping the carrier well before the piston is bottomed out in the bore.

Caleb Perham is a Sonnax product support representative. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.

January 22, 2012

Randall Schroeder

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.