September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

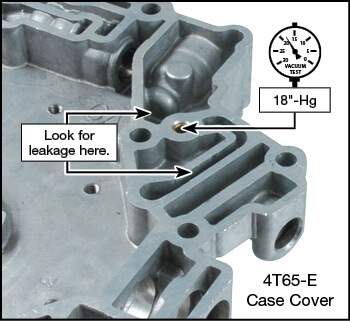

The OE actuator feed limit (AFL) valve routes regulated line pressure to the pressure control solenoid and the 1-2, 3-4 shift signal circuit in GM 4T65-E units. Wear at the AFL valve bore can cause low torque signal and/or low 1-2, 3-4 shift solenoid and shift signal circuit pressure, resulting in Code 1811, maximum adapt or long shift, TCC slippage and wrong gear starts. Bore wear also can cause poor EPC control, leading to high line pressure and TCC piston damage. Sonnax AFL valve kit 84596-02K restores hydraulic integrity to the AFL circuit.

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

September 30, 2005

Gregg Nader

March 21, 2013

January 25, 2023

Maura Stafford