March 17, 2021

Why Do I Drill the Pump? Preventing Excess 6L80 Series Line Pressure with a Drop-In Sonnax PR Valve

Andrew Jessiman

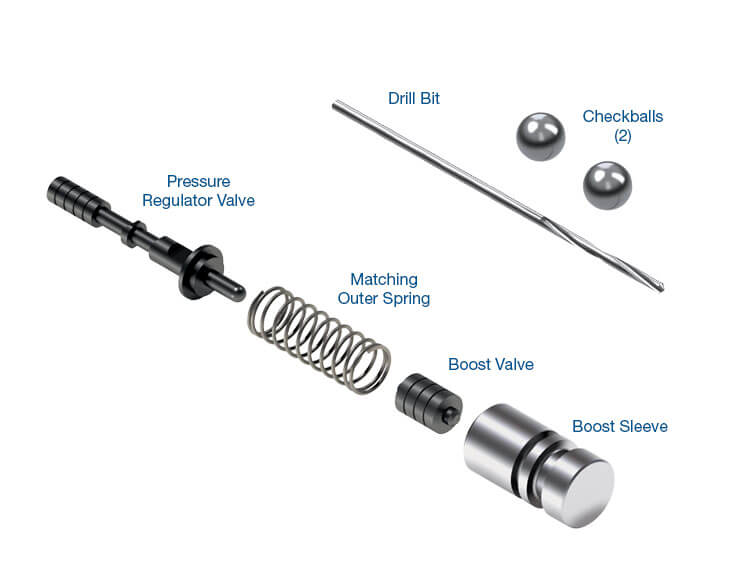

Here in the Sonnax Tech Center, we get a lot of calls about our drop-in GM 6L45, 6L50, 6L80, 6L90 pressure regulator valve asking, “Can I install the valve without drilling into the pump?” and “Why do I need to drill?” The answer is simple: combined with the improved Sonnax valve, drilling ensures you’re making an effective repair that keeps line pressure at OE specifications. Here’s a little background about this valve to help shed more light on the situation.

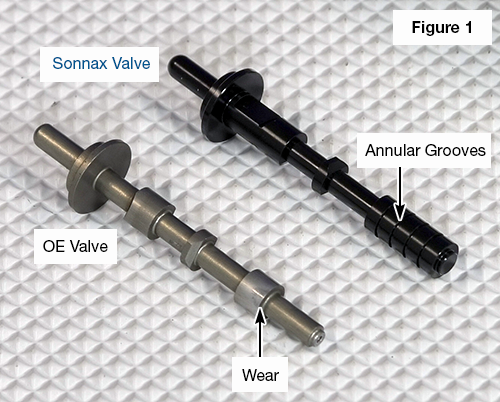

During our research, we found several areas of the bore that commonly wear and need to be addressed. It is common for the balance end of the valve to wear into the casting, resulting in high line pressure, harsh shifts and overheating due to insufficient cooler/ converter lube flow. We also found wear at the outboard spool causing the converter feed pressure to decrease, resulting in low line pressure. Wear at both ends of the valve causing both high and low line pressure unfortunately doesn’t even out, and pressure can be erratic if both sides are worn badly enough.

During design of a drop-in PR valve, Sonnax engineers found it necessary to lengthen critical spools to increase stability and prevent future wear. Since fluid introduced into the bore under pressure can cause the valve to side load and increase bore wear, annular grooves were added to one end of the Sonnax valve to help the fluid surround the valve evenly. This centers the valve in the bore, preventing side loading and unnecessary wear (Figure 1).

| OE vs. Sonnax Pressure Regulator Valves |

|---|

|

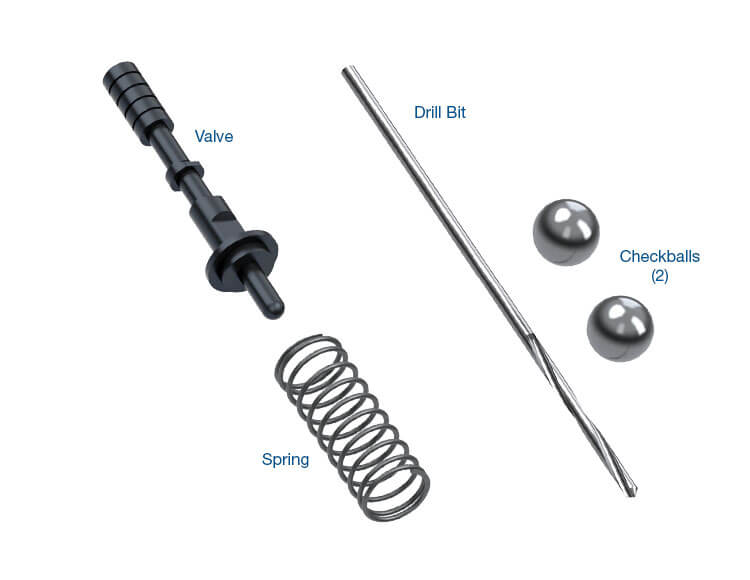

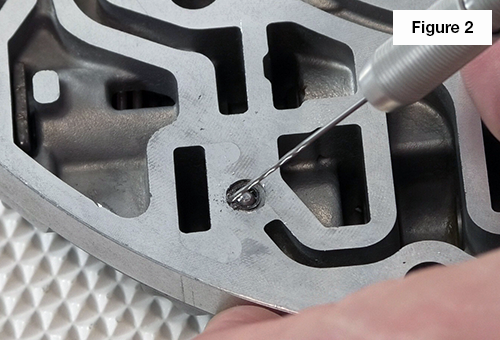

After redesigning the valve, we needed to ensure the proper amount of balance oil was introduced back into the circuit to stay consistent with OE performance. That’s what prompted the additional step of drilling a 45° hole through the adjacent channel: drilling provides balance oil to the valve while in regulating position. If the Sonnax valve is installed without drilling, the result will be excessively high line pressure.

| Figure 2 – Drilling the Pump to Restore Circuit Balance Oil |

|---|

|

Watch this quick video where I show these parts in detail and the simple, step-by-step drilling process.

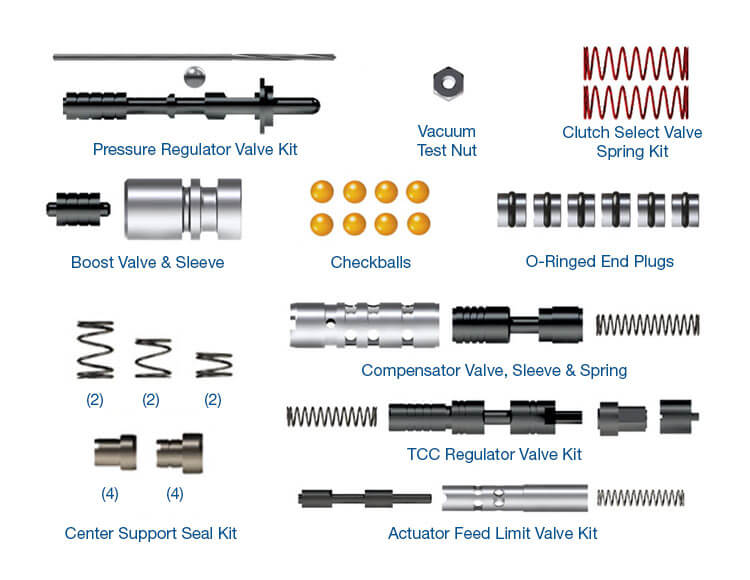

This drop-in Zip Valve™ is available on its own (Part No. 104520-14K) and as part of a more comprehensive Zip Kit® (Part No. 6L45-6L90-ZIP). An oversized version (Part No. 104520-07K) also is available. If you are installing the Zip Kit and decide you don’t want to drill, you shouldn’t install the PR valve, but know that you will be missing out on addressing a common wear area that can contribute to a handful of problems.

Andrew Jessiman is a Sonnax product support representative. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.

Learn More

March 15, 2022

6L80 Series Pump Drilling Demo with Small Drill Bit Vise

Jim Mobley

May 22, 2023

Transmission Repair Tip: How to Use Small Drill Bits with a Portable Drill Motor

Jim Mobley

Related Units

Related Parts

Required

Recommended

6L45, 6L50, 6L80, 6L90

Oversized Pressure Regulator & Boost Valve Kit 104520-07K

-

Helps cure:

- Erratic line pressure

- High line pressure

- Low line pressure

- Clutch slippage

- Harsh shifts

- Low cooler flow

- Burnt clutches

- No cooler flow

- Overheated transmission

- Converter concerns

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.