Symptoms:

- No engine braking in D1

- Breakaway of Low/Reverse clutch

- Burnt Low/Reverse clutch

- Low/Reverse clutch distress

- Low pressure

Cause:

Insufficient L-R clutch holding pressure, due to a minimal area of the modulator plunger valve.Correction:

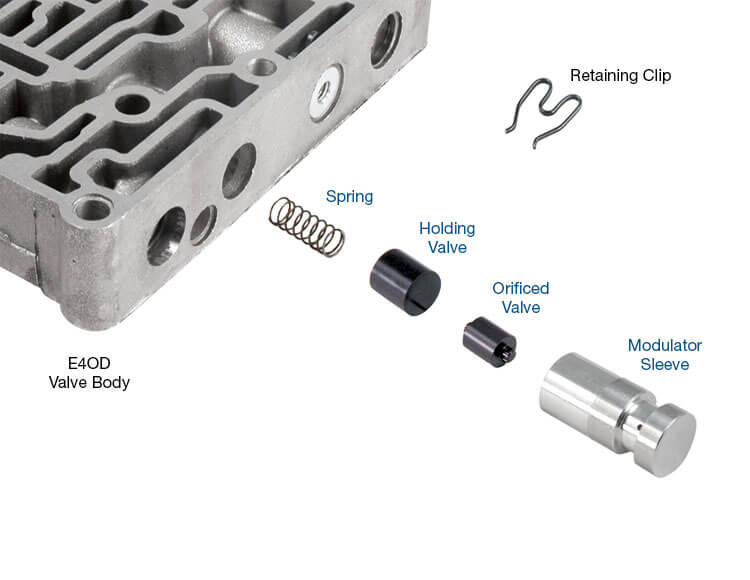

Sonnax drop-in, heavy duty low/reverse modulator sleeve kit is a two-stage valve that ramps the L-R clutch pressure to near double that of an OE valve.4R100 | E4OD

Heavy Duty Low/Reverse Modulator Sleeve Kit

Part No. 36947-09K

Fits '96-later units, uses higher OE ratio

View Instructions Find a DistributorIn Ford 4R100 and E4OD units, the holding capacity of even the largest modulator plunger valve assembly does not supply enough line pressure to the low/reverse clutch to adequately hold the clutch in diesel or heavy-duty applications. This same issue will occur in gas and street applications as the vehicle ages and wear at multiple locations continues to rob line pressure.

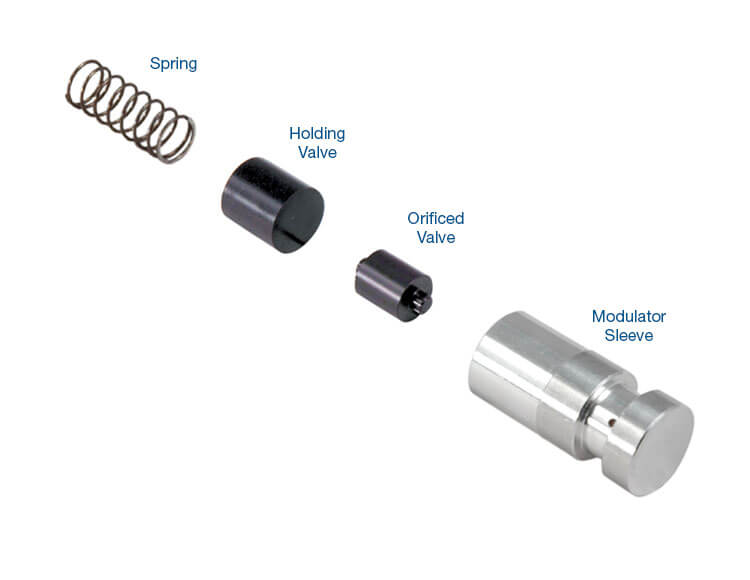

Sonnax heavy duty low/reverse modulator sleeve kit 36947-09K is an innovative, dual-plunger valve drop-in replacement assembly that prevents repeated low/reverse clutch distress and burn-up. The inboard, smaller plunger valve has the ratio of the larger OE plunger valve, but functions primarily as the engagement control for the low/reverse clutch. A small orifice along the valve axis prevents harsh or bang engagements by maintaining a controlled feed flow to the larger, outboard holding valve. This valve provides almost double the holding capacity to the low/reverse clutch as the OE valve.

- Innovative dual-valve design controls clutch engagement while nearly doubling holding capacity

- Hardcoat anodized aluminum valves combat premature wear

- Newly designed sleeve made from highly wear-resistant aluminum alloy

- Drop-in Zip Valve™ parts install quickly and easily

- Modulator Sleeve

- Orificed Valve

- Holding Valve

- Spring

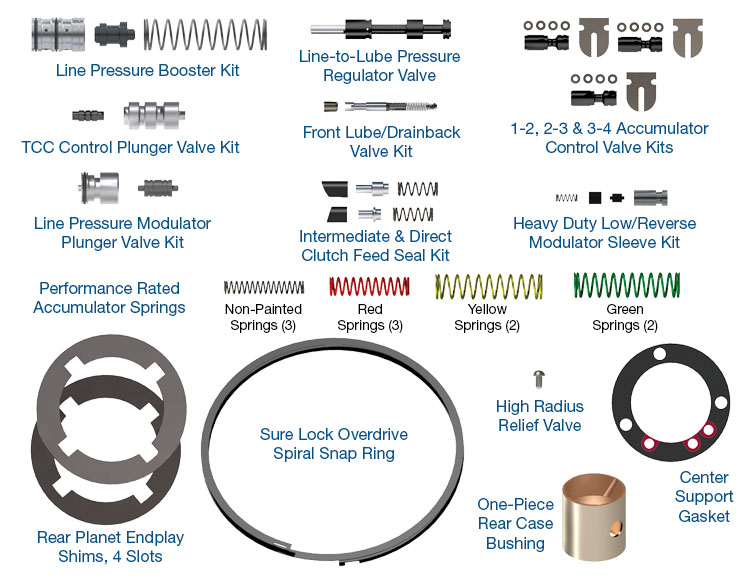

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

Ford E4OD, 4R100 Valve Body Layout