September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

Typical problems in vehicles with a Ford A4LD transmission include low line pressure in forward or Reverse, soft upshifts, delayed Reverse and poor modulator control. These complaints can often be caused by a worn boost sleeve, which allows Reverse and/or TV pressure to cross-leak or exhaust. Sonnax high ratio boost valve kit 56947-02K with O-rings replaces worn parts and offers higher line rise than the OE-style, low-ratio valve.

| 56947-02K | 56947-05K | |

|---|---|---|

| Ratio | High | Low |

| Ø A | .388" | .323" |

| Ø B | .571" | .571" |

| Ø C | .634" | .606" |

| Engine | 4.0L | 2.3, 2.8, 2.9, 3.0L |

September 30, 2005

Gregg Nader

Performing these vacuum tests result in leakage.

Test 1:

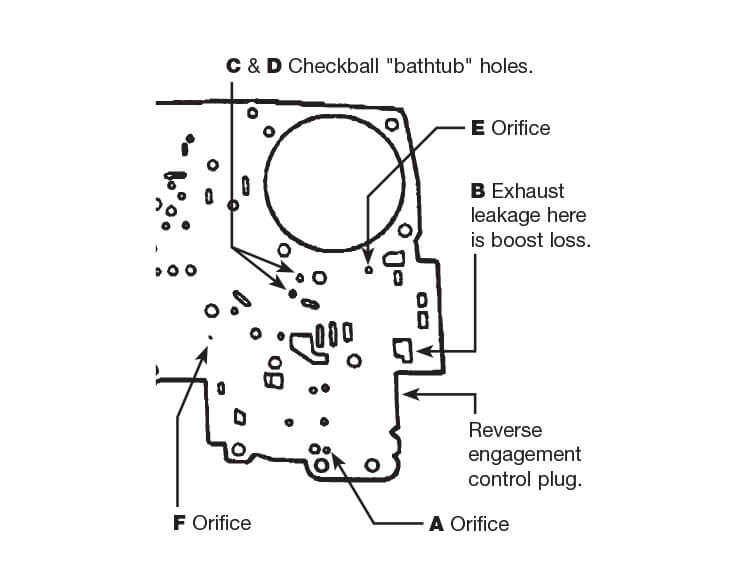

With the manual valve in the reverse position and the separator plate still bolted to the valve body, place a small amount of oil into the "A" orifice. Follow with low air pressure. There should be no oil or air leakage in the exhaust port at "B," If there is, the boost valve is worn at the reverse land and should be replaced.

Note:

During test of Reverse circuit, if excessive oil loss is visible at the Reverse engagement control plug, the plug is either installed backward (should be large diameter outward) or the plug or bore is worn. This wear will reduce Reverse boost effectiveness.

Test 2:

Place a small amount of oil in the checkball hole "C" or "D." Follow with low air pressure while plugging the opposing hole. There should be no oil or air leakage at orifice "E" location. If leakage occures, the boost valve assembly is worn and should be replaced.

Note:

To ensure that the pressure regulator balance circuit is functional, perform a vacuum test at "F." A worn bore will leak to filter suction hole. Many poor converter charge and engagement concerns are related to bore valve wear here. Worn bores can be repaired by using Sonnax oversized pressure regulator valve kit 56947-06K.