September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

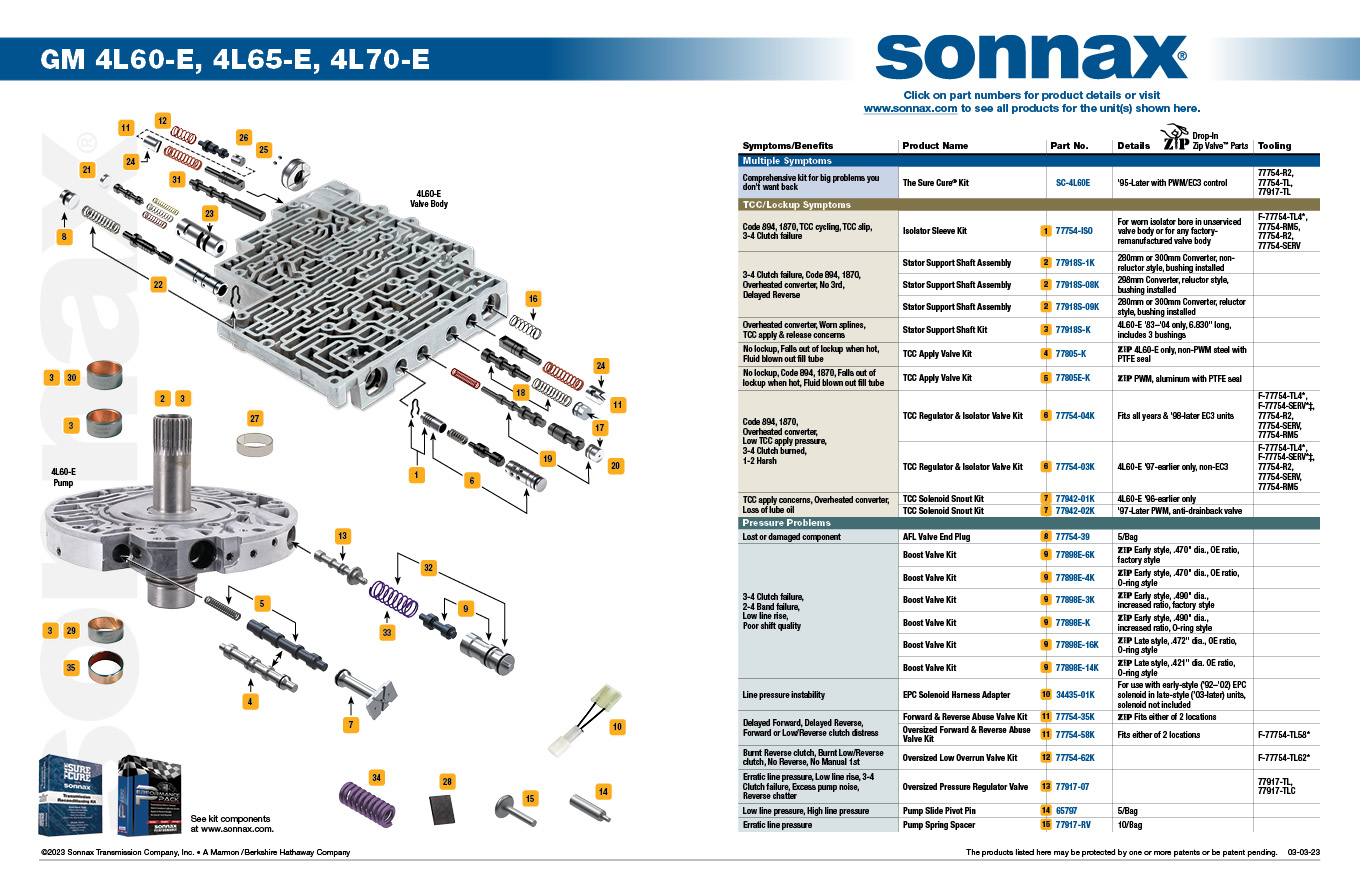

The plastic OE torque converter clutch solenoid snouts are prone to breakage causing them to leak oil that should be directed to the converter clutch apply valve. Until now, your only option was to replace the entire OE harness or purchase an aftermarket solenoid and splice it into the existing harness. Sonnax TCC solenoid snout kit 77942-01K allows the OE solenoid in GM 4L60 and '96-earlier 4L60-E units to be rebuilt to better-than-new condition. Sonnax also offers TCC solenoid snout kit 77942-02K that eliminates the need for the damage-prone plastic OE drainback valve in for ‘97-later PWM units. The solenoid snout is made of aluminum for better wear resistance and durability.

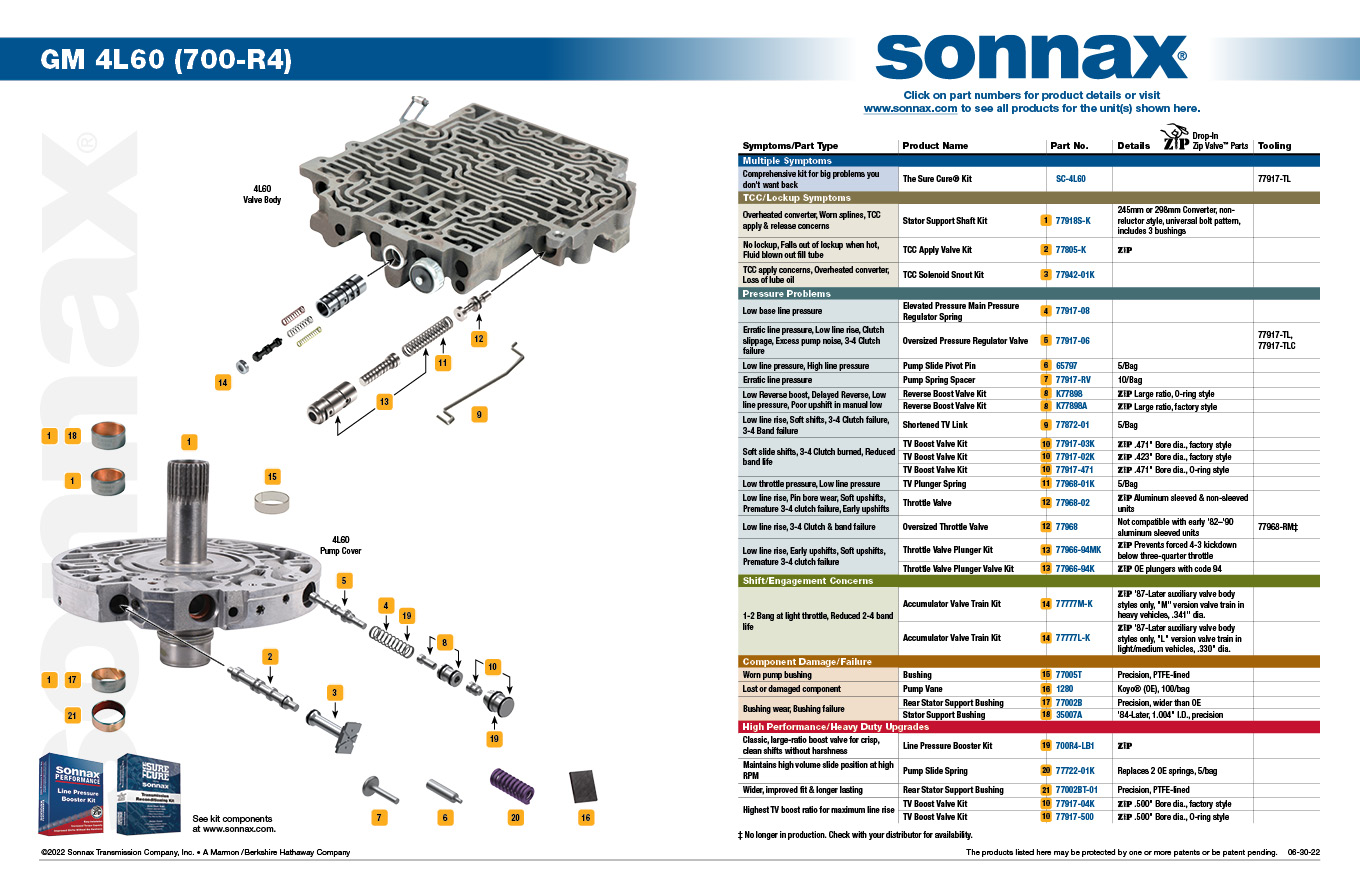

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

September 30, 2005

Gregg Nader

December 22, 2014

Tory Royce