February 21, 2013

Symptoms:

- Reverse slip

- Gear ratio codes

- 3rd Slip

- 4th Slip

- Direct clutch burned

- No Reverse

Cause:

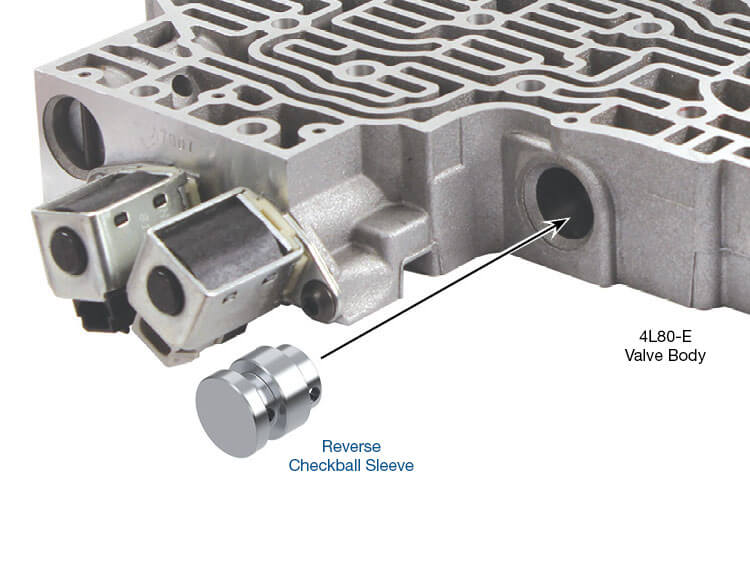

Excess wear in Reverse checkball sleeve prevents proper application of direct clutches.Correction:

Restore hydraulic control and prevent premature wear by installing Sonnax drop-in reverse checkball sleeve.4L80-E | 4L85-E

Reverse Checkball Sleeve

Part No. 34200-38

Fits units '95-later.

Package Quantity: 4

You need this if... View Instructions Find a DistributorVehicles with '95-later GM 4L80-E and 4L85-E transmissions commonly exhibit wear in the Reverse checkball sleeve located in the 3-4 shift valve bore. This issue is caused by normal movement of the checkball within the sleeve over time. As wear progresses, sealing function of checkball becomes compromised and results in loss of apply pressure to direct clutches. Consequences of this pressure loss are slipping or no 3rd, 4th, and Reverse gears, burnt direct clutches, and ratio codes.

Installing Sonnax Reverse checkball sleeve 34200-38 restores the hydraulic integrity of this circuit to reestablish normal shift operation and performance.

- Sleeve is manufactured from highly wear-resistant aluminum for maximum life

- Drop-in Zip Valve™ parts install quickly and easily

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

GM 4L80-E, 4L85-E Valve Body Layout

You need this if...

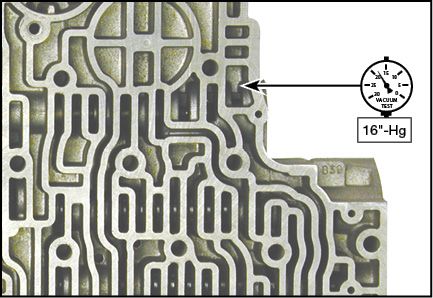

Vacuum testing at the port(s) indicated fails to hold the recommended minimum in-Hg., or if wear is visually detected.