October 31, 2014

Symptoms:

- Code P0741, P0742

- No lockup

- TCC slip

- Loss of fuel economy

- Low TCC apply pressure

- Overheated fluid & TCC lining

- Harsh TCC apply

Cause:

Bore wear at the TCC regulator valve reduces TCC apply and converter charge pressure. If valve sticks, TCC slip or harsh apply will result.Correction:

The Sonnax drop-in TCC regulator valve kit has extended spool lands to operate in unworn areas of the bore. A modified shuttle valve with added stability prevents valve train from sticking.6T30 (Gen. 1) | 6T30 (Gen. 2) | 6T31 (Gen. 3 6T40) | 6T35 (Gen. 3 6T40) | 6T40 (Gen. 1) | 6T40 (Gen. 2) | 6T41 (Gen. 3 6T40) | 6T45 (Gen. 1) | 6T45 (Gen. 2) | 6T46 (Gen. 3 6T40) | 6T50 (Gen. 1) | 6T50 (Gen. 2) | 6T51 (Gen. 3 6T40)

TCC Regulator Valve Kit

Part No. 144740-38K

You need this if...

View Instructions

Find a Distributor

Vehicles equipped with GM Gen. 1 and 2 6T30/40/45/50 and 6T35/31/41/46/51 (Gen. 3 6T40) transmissions can exhibit a number of TCC apply issues caused by bore wear at the TCC regulator valve. Slipping TCC, no TCC apply, fluid overheat and suffering fuel economy are common results of this wear. If the valve becomes stuck in the apply position, harsh TCC apply will be the consequence. If the valve is stuck in the release position, no TCC apply or TCC slip will occur.

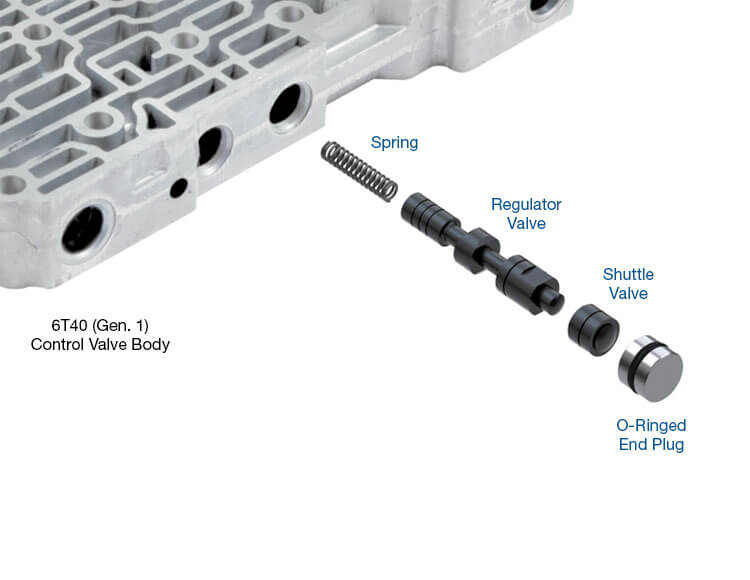

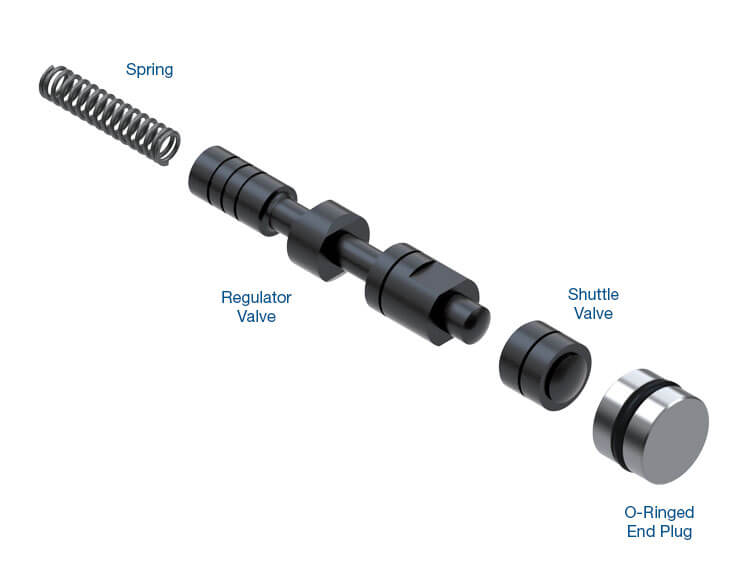

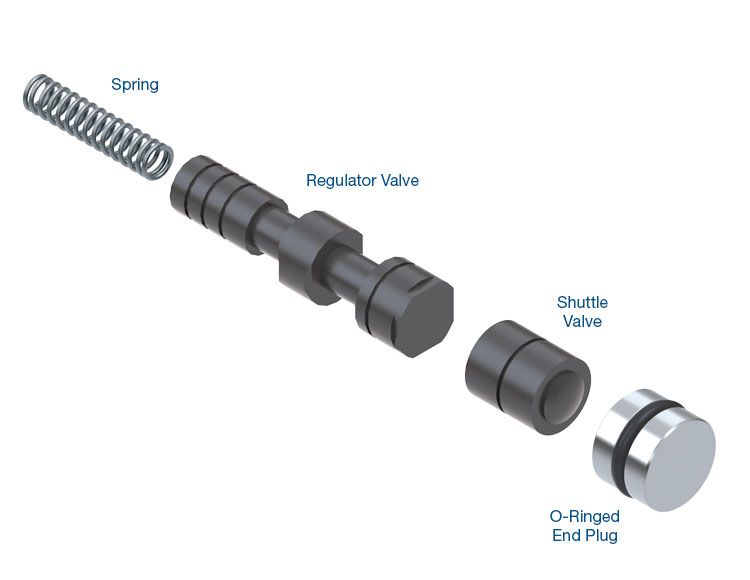

For moderately worn bores, installing Sonnax TCC regulator valve kit 144740-38K will restore proper valve function, resulting in proper TCC apply. The valve lands have been lengthened significantly, allowing the valves to operate in unworn portions of the casting bore to effectively seal against leakage. The shuttle valve has been modified to directly engage with the regulator valve, adding stability and guidance to prevent cocking in the bore, which causes the valve train to stick.

- Hardcoat anodized aluminum valves combat premature wear

- Inboard and outboard spools on the TCC regulator have been made significantly longer to operate in unworn portions of the casting bore

- Modified shuttle valve adds stability and guidance to prevent valve train sticking

- O-Ringed end plug positively seals solenoid apply pressure to prevent leakage

- Drop-in Zip Valve™ parts install quickly and easily

- Regulator Valve

- Shuttle Valve

- Spring

- End Plug .511" O.D.

- O-Rings (2) .070" Thick, 1 Extra

- End Plug .600" O.D.

- O-Rings (2) .103" Thick, 1 Extra

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

GM 6T30/40/45/50 (Gen. 2), 6T40 (Gen. 3) Valve Body Layout

You need this if...

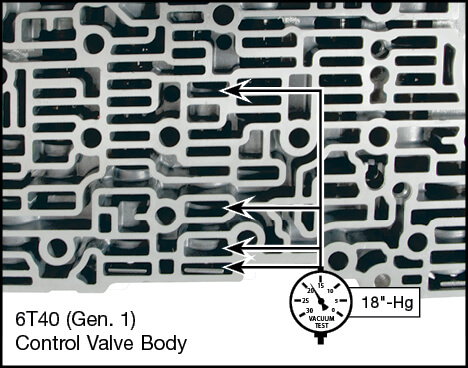

Vacuum testing at the port(s) indicated fails to hold the recommended minimum in-Hg, or if wear is visually detected.