Clutch Control Valves in Later Units vs. Shift Valves in Early — Why Wear is Critical to Detect

Clutch control/regulator valves in today’s transmissions are quite different than the shift valves of previous transmission designs. Hydraulic leaks in these units are critical to detect, so understanding how the valves work will help you diagnose problems before a repair job turns into a comeback.

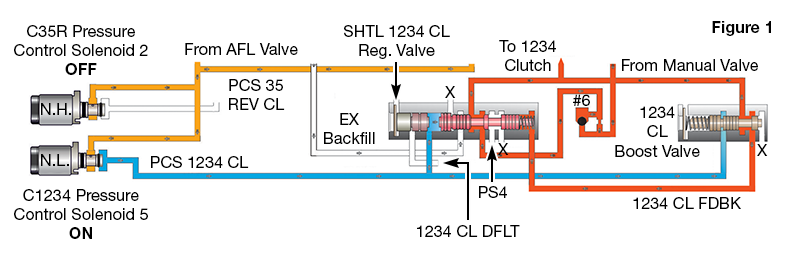

Shift valves from early transmissions were the gatekeepers for connecting line pressure to an awaiting clutch or servo to make gear changes happen by either being at rest or being fully stroked against a return spring. Control of these valves, in the beginning, was typically through governor pressure and, as vehicle speed increased, governor pressure would increase stroking the shift valve to connect line pressure to a clutch and/or servo to upshift or downshift the transmission. As time progressed, governor control morphed into on/off solenoid control, as engine control systems capabilities increased. This increase in engine management gave transmission control the ability to be more precise. Figure 1 shows an example of today’s valve trains in a 6L80 application and how the 1-2-3-4 clutch regulator valve and latch valve work together to bring the clutch on seamlessly.

| Figure 1 – Beginning of Clutch Engagement (6L80) |

|---|

|

The illustration shows how — as the duty cycle from the 1-2-3-4 pressure control solenoid increases — the 1-2-3-4 regulator valve is stroked to the right, which connects 1-2-3-4 feed pressure from the manual valve to 1-2-3-4 apply pressure. This apply pressure is connected to the latch valve when the solenoid duty cycle is being ramped up. The passage in the latch valve, at this duty cycle, connects 1-2-3-4 apply pressure to the spring side of the 1-2-3-4 regulator valve, which helps control the apply rate of the 1-2-3-4 clutch.

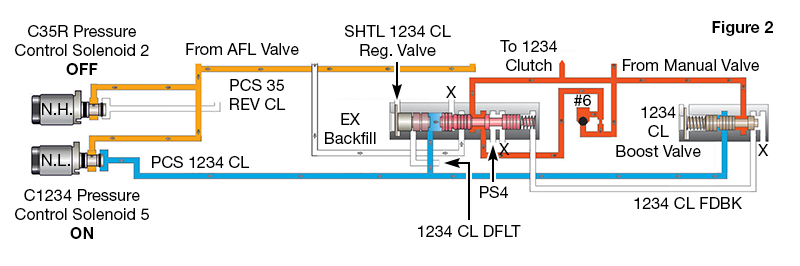

Once the TCM sees that input speed is dropping, the duty cycle will increase and the connection to the spring side of the valve will be closed by the position of the latch valve. Figure 2 shows this illustration with the clutch fully applied. The entire process of this clutch apply is typically complete in approximately 0.6 seconds, so the integrity of the hydraulic circuits is critical.

| Figure 2 – Clutch Fully Applied (6L80) |

|---|

|

Control of these valve trains are quite different in today’s transmissions, as you can see in the example of the 6L80. Electronic control has come a long way since the day of the governor, and clutch release and apply have become a lot more precise as the result. Wear in clutch control and clutch regulator valves compromises pressure, flow and timing, which can cause numerous complaints such as shift overlap issues (a flared shift), a bind up on an upshift or downshift, delayed engagements and low line pressure.

Identifying leaks by vacuum testing clutch regulator/control valves, their end plugs and any associated latch/boost valves in these circuits are critical to maintaining a warranty. Failure to find these problem areas could shorten the life span of the transmission and cause a costly comeback.

Related Units

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.