Building a Reaming and Inspection Station

Seth Baldasaro

As valve bodies continue to evolve and become more complex, rebuilders are finding it increasingly necessary to have a central location for bench reaming and inspection of valve bodies. Many transmission shops have found – to their surprise – that building an inspection and reaming station can be inexpensive and that a station can be put together from many items already available in the shop.

The station may be as simple as an existing 20-gallon parts washer, submersible pump, flexible nozzle, filter and bench-mounted 360-degree swivel head vice (see Figures 1 and 2) and a Sonnax valve body reaming fixture (VB-FIX).

However, the station can be more elaborate and offer additional capabilities, such as vacuum testing, Wet Air Testing, hydraulic testing, valve body tool storage and surface finishing.

The foundation for a test and rebuild center that is more advanced than the one shown above is a sturdy bench with leg base plates to anchor it to the floor. An estimate for the size of the bench would be 3 feet by 4 feet, with a height of 3 feet.

Under the bench top, you’ll need to build a shelf for a 3- to 5-CFM vacuum pump. The vacuum pump will require a gauge and hoses, plumbed for easy access for circuit testing. The bench should also be pre-wired with a 4-plex outlet for vacuum pump and electrical accessories, such as Dremel tools. Plumb the bench for three lines of regulated air supply that can be quickly coupled to the main shop air.

Under the bench will live a drain shelf and tank for cutting fluid, to include a reaming fluid circulation pump. There should be a filter element to catch reaming chips before cutting fluid drains back to the tank. This filter and shelf can be as simple as an existing 20-gallon parts washer tank (with short legs) on 360-degree casters to roll under the bench when not reaming. A 5-foot hose from the cutting fluid pump will require a flex neck and spring clamps to allow multiple fixturing.

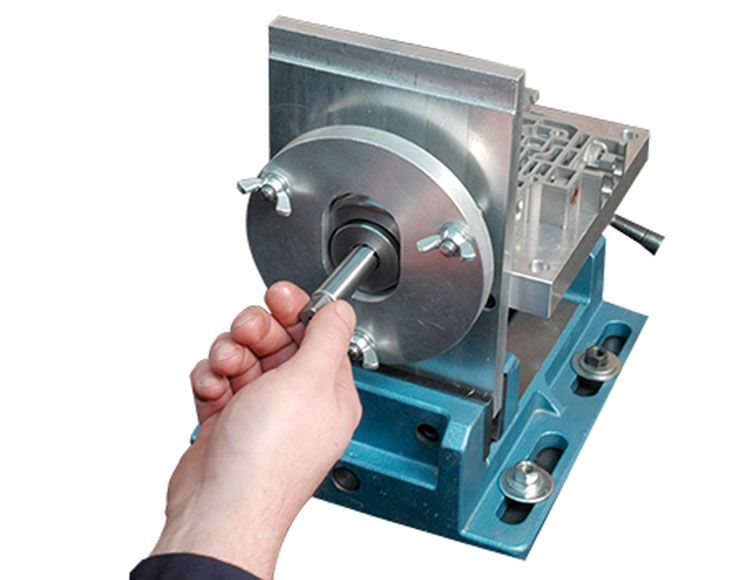

The Sonnax valve body fixture (VB-FIX) can be swivel-mounted onto the bench. There must be a pin with a length of at least 12 inches to allow an extension away from the bench for larger valve bodies. The valve body fixture, although designed to work with specific tools, may be used as a universal mount for all valve bodies: However it can have 1/4-inch holes added to both faces to fasten various valve bodies when non-guided reamers are used.

The Sonnax valve body fixture (VB-FIX) can be swivel-mounted onto the bench. There must be a pin with a length of at least 12 inches to allow an extension away from the bench for larger valve bodies. The valve body fixture, although designed to work with specific tools, may be used as a universal mount for all valve bodies: However it can have 1/4-inch holes added to both faces to fasten various valve bodies when non-guided reamers are used.Seth Baldasaro is the director of strategic accounts.

Related Parts

Required

Recommended

Valve Body Reaming Fixture VB-FIX

-

Helps cure:

- Some worn valve & pump bodies cannot be salvaged

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.