April 27, 2016

Understanding & Overcoming the Powerglide Servo Pin Bias Effect - Part 2

Note: Read Part 1 of this article for more in-depth technical information and a closer look at how the Sonnax race-calibrated servo return spring can be used in OE and aftermarket servos to offset the pin bias effect.

"Pin bias" refers to flaws in the outdated Powerglide servo design that are responsible for otherwise unexplained band failures, input shaft failures and staging issues. Overcoming the pin bias effect is CRITICAL for improving the reliability of this capable transmission. Only the Sonnax Smart-Tech® servo can do it, making this “ratio-style” servo the ultimate choice for running Powerglides in ever more extreme applications.

Burnt bands, broken parts and inconsistent operation have plagued the Powerglide for years, leading many to give up on this transmission and seek other options.

If the servo release spring is too light in a racing Powerglide, the band doesn’t release properly and drags on the drum. When band drag occurs, it robs power and slows the car, while burning the band and overheating the transmission. A dragging band also will cause a tie-up on the shift as the high clutch applies before the band is fully released, resulting in shafts that break or twist during the shift to high gear.

Changing to a stronger servo spring to improve servo release only aggravates staging issues. A stronger spring causes the servo to momentarily release as the trans brake is applied, resulting in unintended Reverse.

This video dramatically shows how the OE Powerglide servo performs at high pressures when fitted with OE and aftermarket springs.

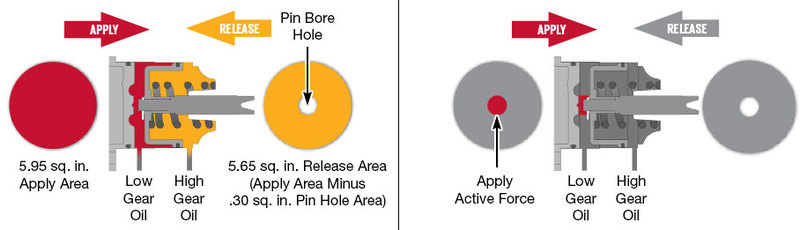

The root of the problem is the primitive Powerglide servo design with an equal seal diameter for both apply and release sides (Figure 1). The release area excludes the .3 sq. in. area of the pin bore diameter, which means the apply area is larger and the release area is smaller, exactly the OPPOSITE of modern servos that are NOT susceptible to pin bias issues.

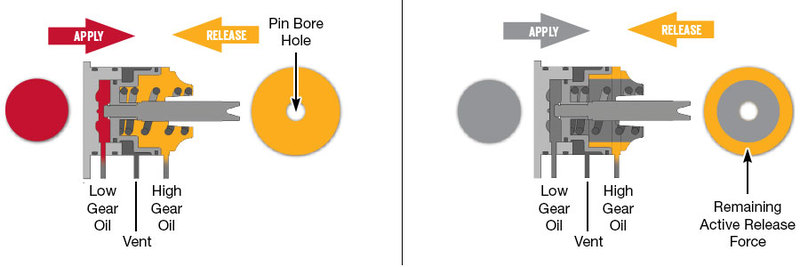

Not only does the Powerglide servo have zero hydraulic release force, but due to the pin bias effect, there is ALWAYS some apply force for the spring to overcome. This residual pin bias/servo apply force varies with line pressure, therefore any change in pressure affects the spring action and servo release. If the spring is too weak, the band drags, if it’s too strong, net apply force is reduced and – while staging – the servo can release. Modern servo designs with their larger release area benefit from a hydraulically powered release where spring action is not as critical (Figure 2).

The pin bias-related issues have persisted for decades and only become worse as line pressure and power levels have increased. Converting the Powerglide servo from an improper apply/release ratio to a modern proper apply/release ratio was never thought possible.

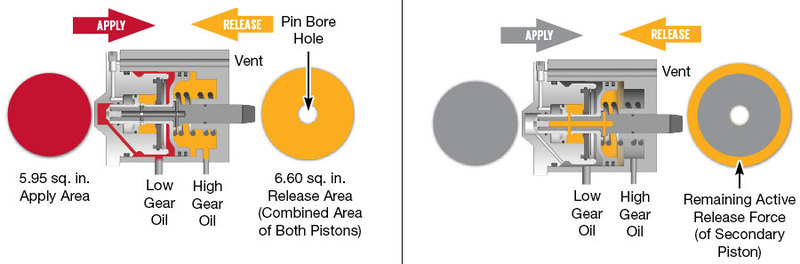

Sonnax is the first to fully understand and overcome the pin bias by developing an innovative new “ratio-style” servo for the aftermarket. This unique, dual-piston servo features an apply area equal to the original Powerglide design, but a LARGER release area just like modern servos with hydraulically powered release (Figure 3).

Stop struggling with the old Powerglide servo design!

The Sonnax Smart-Tech servo advances the Powerglide transmission to new levels that back up extreme horsepower with never-before-seen reliability. If you've upgraded other components and are still struggling with servo-related problems, the Smart-Tech servo is a key piece to solving this puzzle.

Proper servo function is critical for many areas of the Powerglide transmission, especially at high pressures. Band failure, broken shafts and staging issues can be traced directly back to the flaws in the OE servo design. The diagrams below illustrate why the OE servo is incapable of full release in high gear, and a more modern servo like the Sonnax Smart-Tech is the only way to fully avoid that crippling limitation.

Full Reaction Areas |

Remaining Reaction Areas

|

|

|---|---|---|

| Figure 1 | ||

OE POWERGLIDE SERVOInherently flawed, spring-powered design suffers from an improper apply/release ratio and crippling pin bias issues. |

|

|

| Figure 2 | ||

MODERN SERVO (C4, C6, 4L60)Efficient hydraulic design with proper apply/release ratio avoids all pin bias problems. |

|

|

| Figure 3 | ||

SMART-TECH® SERVOUnique hydraulic design converts the Powerglide servo to the proper apply/release ratio, eliminating the pin bias effect. |

|

|

Learn more about the Sonnax Smart-Tech ratio-style servo kit, the ULTIMATE Powerglide servo for even the most extreme applications.

Learn More

April 26, 2016

Prevent "Mystery" Powerglide Band Failures by Overcoming the Servo Pin Bias Effect

May 09, 2017

From the Bench: Building a World‑Class Powerglide Racing Transmission

August 23, 2017

First, Do No Harm: Things You Should Know about Performance Servos

Gregg Nader

Related Units

Related Parts

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.