How to Avoid a Dipstick Move in 4L60-E Series Transmissions

Jason Larochelle

Ensuring your fresh build has adequate fluid is crucial to the life and longevity of a transmission. No competent builder would knowingly let a vehicle leave their shop when the transmission is under or overfilled by a quart. With a small parts compatibility issue, that could happen unknowingly if you aren’t careful.

The GM 4L60-E series has long been the go-to transmission for engine swaps when space is in short supply. These units don’t require cutting floor pans in most cases, unlike their bigger brother the 4L80-E. Although the 4L60-E, 4L65-E and 4L70-E don’t support nearly as much power in stock form as the 4L80-E, there are plenty of aftermarket parts to make them reliably live all the way up to 1,000HP. Based on the 700-R4 that General Motors utilized from 1982 until 1992, the 4L60-E series was used from 1993 until 2013 when it was replaced by the 6L80. They were installed in just about everything GM sold in a rear-wheel-drive platform such as the Silverado, S-10, Corvette, Astro, etc. The transmission underwent many changes and design updates during its lifetime, which can lead to an obscure parts-compatibility issue during rebuilding.

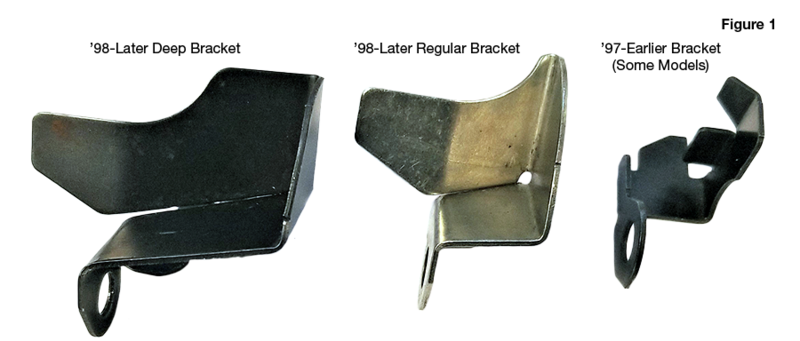

One of the changes over the years could easily be overlooked: the dipstick. A big change occurred in 1998 when the 4L60-E series received a deeper transmission oil pan on the C/K/G trucks and vans to increase the fluid capacity in the larger vehicles. The addition of this deeper pan was accompanied by a longer dip stick, tube and dipstick stop bracket. Meanwhile, models with the standard pan received a revised-design dipstick stop bracket with the same height as the previous design, but shorter than the deep pan dipstick stop. In the early years of the 4L60-E series the dipstick bracket was not used on all vehicles, but after 1998, all models besides the Corvette utilized one. Figure 1 shows the three different stop brackets.

| Figure 1 – Dipstick Stop Brackets |

|---|

|

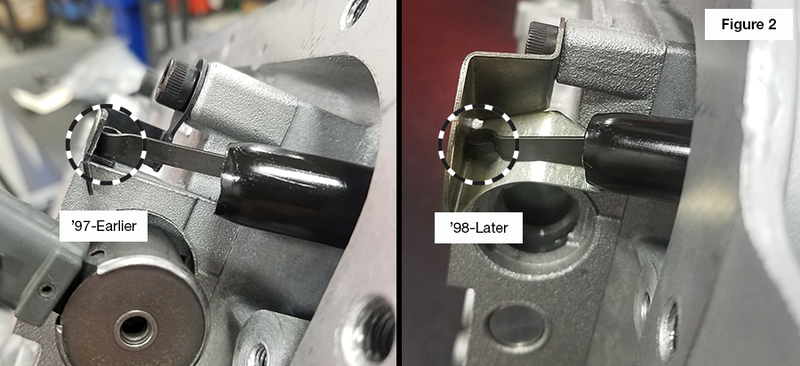

The reason for the redesign was to create a larger target for the dipstick to stop against. Figure 2 shows the small contact area for the ’97-earlier dipstick compared to the contact area for the ’98-later dipstick and new deep pan bracket.

| Figure 2 – Dipstick Contact Areas |

|---|

|

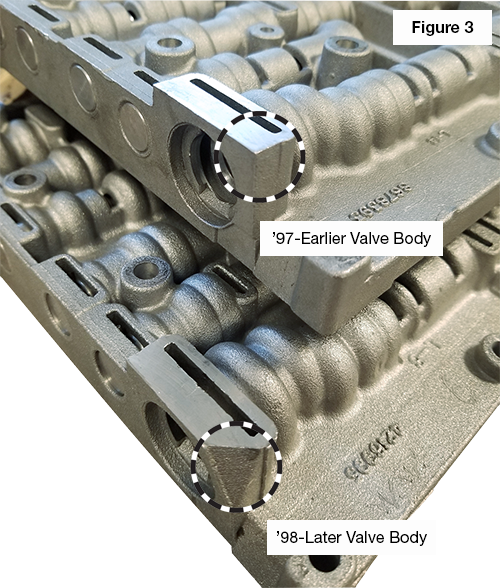

Another change that occurred in 1998 was the addition of a small chamfer on the valve body itself to facilitate the use of both the new-design stop brackets (Figure 3).

| Figure 3 – Valve Body Casting Differences |

|---|

|

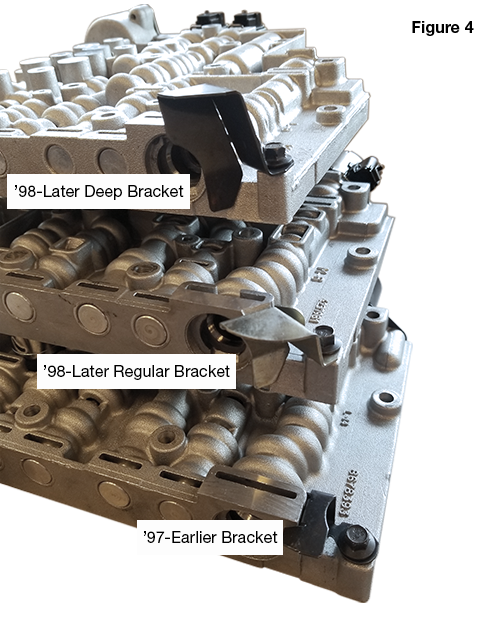

Since previous 4L60-E series valve bodies did not have this chamfer, this prevents the new-design stop brackets from being installed on anything pre-1998. The old-design stop bracket could still be installed on a ’98-later standard pan without any issues, but would not be favorable considering the improvements made to the new bracket. Figure 4 shows the three different combinations of brackets and valve bodies.

| Figure 4 – Valve Bodies & Brackets |

|---|

|

The confusion begins when 4L60-E series units are swapped into hot rod projects or cores are purchased to replace a stock unit. Through testing, here are some possible combinations and the outcomes.

Regular Dipstick, ’97-Earlier | Regular Dipstick, ’98-Later | Regular Dipstick, Tube & Deep Pan ’98-Later | Deep Dipstick ’97-Earlier | Deep Dipstick ’98-Later | Deep Dipstick, ’98-Later | Deep Dipstick, ’97-Earlier | Deep Dipstick & Pan, Regular Tube ’98-Later | Deep Dipstick, ’98-Later | |

| Old-Design Bracket | OK | OK | Higher Fluid Capacity | Part Interference | Part Interference | Part Interference | Part Interference | Part Interference | Part Interference |

| New-Design Bracket | Part Interference | OK | Higher Fluid Capacity | Part Interference | Part Interference | Part Interference | Part Interference | Part Interference | Part Interference |

| New-Design Deep Bracket | Part Interference | Potential to Overfill by .75 qt. | Potential to Overfill by .75 qt. | Part Interference | Potential to Underfill | OK | Part Interference | Part Interference | Part Interference |

| No Bracket | Potential to Overfill by .75 qt. | Potential to Overfill by .75 qt. | Potential to Overfill by .75 qt. | Potential to Underfill | Potential to Underfill | Potential to Overfill by .5 qt. | Potential to Overfill by .5 qt. | Potential to Underfill | Potential to Underfill |

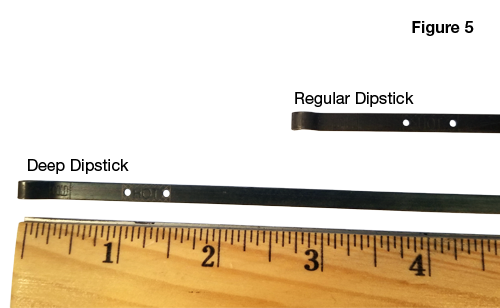

As you can see, there are many combinations, and some are not favorable with potential to underfill or overfill. The biggest issue is when a deep bracket is used with a regular dipstick or no bracket at all is used. Dipsticks are made longer than they need to be on purpose so that they make contact with the stop bracket and provide an accurate fluid level reading. Using the incorrect or no bracket at all allows the dipstick to read lower into the pan, giving the illusion the level is at normal capacity when it actually isn’t. In the regular pan setup, neglecting to install the corresponding bracket could result in underfilling up to .5 quart. The deep dipstick without its bracket is up to a .75 quart underfill. Another issue is using the deep dipstick and tube with a regular pan. Checking the level using the dipstick, it will read in normal operating range, but your fluid capacity will be much lower than it should be. It will be quite obvious if you tried to use the deep dipstick with a regular length tube and any of the brackets, however it is possible to incorrectly install this setup if one were to neglect using a stop bracket, which would lead to underfilling the transmission significantly. See Figure 5 for the length difference between the two regular and deep dipsticks.

| Figure 5 – Dipstick Lengths |

|---|

|

Other manufacturers use similar dipstick stops in different locations. One transmission that has been heavily modified lately is the 68RFE found in Dodge diesels. These transmissions are often behind modified, 1,000HP, turbo diesel monsters that almost have matching torque and horsepower numbers. To make the 68RFE survive in this environment, a variety of aftermarket parts are utilized, including deeper oil pans for more capacity. The problem is that some aftermarket deep pans aren’t designed with the dipstick stop that factory pans are designed with, which creates the same underfilling situations as we’ve illustrated with the 4L60-E series. This is certainly an issue that you should look into to ensure that your transmission has adequate fluid capacity to live a long healthy life.

Jason Larochelle is a Sonnax product support representative. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.

Related Units

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.