September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

This part only fits PWM units, and mismatching PWM and non-PWM valves will cause rapid converter failure.

Identifying PWM vs. Non-PWM Units

If the OE valve features one spool at the location indicated here, you are working on a PWM unit. If the OE valve features double spools, you are working on a non-PWM unit and must use Sonnax TCC apply valve kit 77805-K. Do not rely on the OE valve material (steel vs. aluminum) to determine for whether the unit is PWM, as some early PWM pumps used steel TCC valves like the non-PWM pumps.

Vehicles with GM 4L60-E, 4L65-E and 4L70-E transmissions have numerous converter overheat lockup complaints. These include no lockup or lockup immediately after 2nd Gear when fluid warms up, caused by valve bore wear. Frequently, the solenoid will have no control over the valve's position. Often converter feed oil will leak past the OE spool, which, added together with orificed signal oil will be more than the solenoid can exhaust. This may completely stroke the valve into the lockup position and create a "no power" or "no brake cancel" condition. Oil cross-leaks may float the valve into a mid-way position and restrict cooler flow, which burns up the converter. Sonnax TCC apply valve kit 77805E-K will eliminate the bore cross-leakage. This precision valve has a PTFE seal to prevent the cross-leaking of converter signal and converter feed oil.

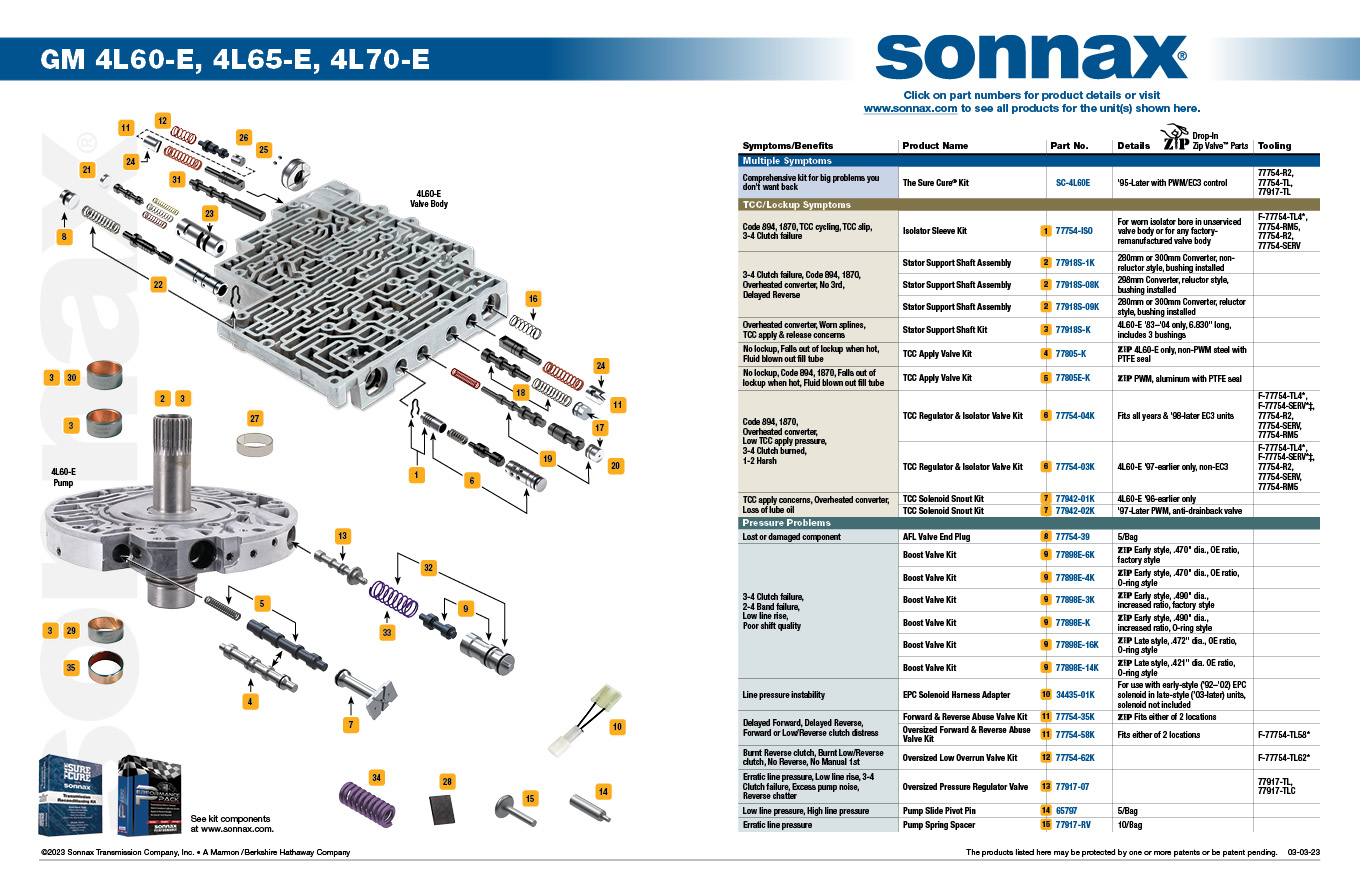

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

September 30, 2005

Gregg Nader

December 22, 2014

Tory Royce

January 21, 2013