Understanding Cooler Control Valves: What Thermal vs. Pressure Control Means for Your Build

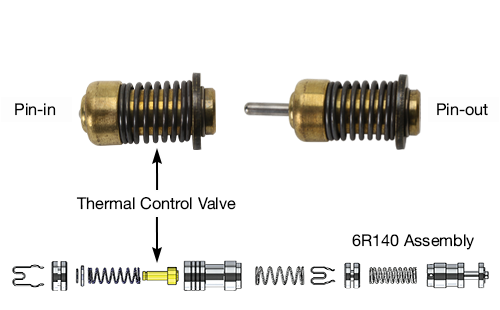

The purpose of a thermal control valve within an automatic transmission is to direct cold versus hot torque converter oil between two circuits. Those circuits are selected by a wax-filled thermal element that positions a pin (Figure 1). “Pin-inward” is the cold position, and “pin extended” is at the operating temperature. “Pin-in” directs converter oil to the front pump bushing and lube circuit. “Pin-out” moves the cooler control valve, directing converter oil to the radiator cooler.

| Figure 1 – Thermal Control Valve Pin-in vs. Pin-out |

|---|

|

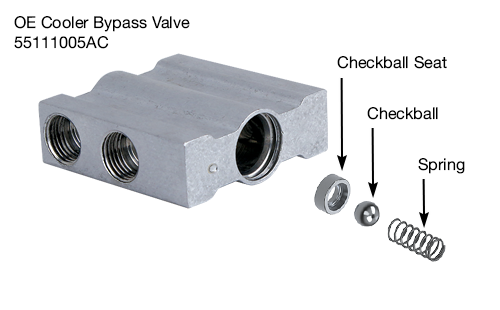

Thermal control valves should not be confused with the cooler pressure relief valves. The Chrysler/Ram pressure sensitive bypass is mounted to the radiator and designed to open at 55 psi of head pressure. Head pressure develops from a restricted cooler due to gelled ATF or contamination (Figure 2).

| Figure 2 – At-Risk Bypass Components |

|---|

The seat wears or becomes contaminated and the spring becomes weak or breaks. |

We find pressure sensitive relief valves behind the pump in Chrysler 41TE and 62TE applications, mounted to the case on a Ford 4R100 (Sonnax 36605-02K) or in the valve body of an RE5 (Sonnax 63741-07K).

Failure Modes

The converter is a heat-generating component due to the work (torque transfer) and the oil shear taking place. In cold weather conditions, the warming ATF is expedited to lube bushings through the closed thermal element until proper ATF temperature is reached (approximately 130°F) when the element opens to allow flow through the cooler.

In reference to the thermal element, if the pin-out does not occur, does not fully extend or extends and then retracts to mid-point, converter outflow can be restricted or directed internally of the transmission, never allowing flow to the cooler. In this condition, the converter may overheat, transmission temperature codes could set, and converter clutch apply can be affected. When pressure relief valves remain open due to a weak spring or seat contamination, they can drop converter pressure and create high stall or lockup issues.

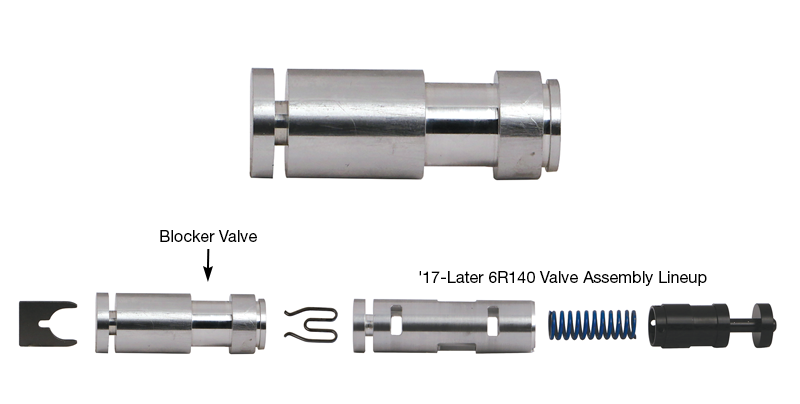

Blocking the Thermal Control Valve

If this is a heavy-use vehicle that frequently operates in the hot transmission fluid range, blocking the control valve will ensure full flow to the cooler at all times (Figure 3). Blocking either the thermal or the pressure relief type of control valve will ensure flow and charging of the cooler circuit. If either control valve is blocked into the full flow position, synthetic ATF should be used for temperatures that drop below 0°F.

| Figure 3 – 6R140 Thermal Bypass Blocker Valve |

|---|

|

Note: Blocking a thermal control valve may negatively affect shift quality and adaptation. Late-model transmissions use temperature control to select the shift program, pressure rise and converter clutch apply.

Qualifying Thermal Control Elements

Testing a thermal element requires a controlled heat, such as a slow cooker with a separate thermometer. Place the element in the pot with ATF and verify the pin fully extends. The key points of this test include the specific temperature, the length of the pin when extended and the resistance to push the pin back in. Partial stroke of the control valve occurs if the pin extends part way or extends fully but pushes in easily. Specifics vary for each thermal application, but usually have pin-out at 125°F or 135°F, etc.

With either thermal or pressure control, ensure the transmission fluid has reached operating temperature prior to a prolonged drive and definitely before the vehicle has been released. If the thermal valve has not opened, the cooler circuit will not be charged, and the vehicle can return with a low fluid level.

To expedite the temperature rise, the shop may perform a stall test (drive range/brakes applied). Transmission manufacturers do not suggest a high-torque stall test to increase heat within the torque converter. Remember that as the transmission temperature rises on the scan tool, the converter out temperature is greater.

The transmission temperature at the valve body thermistor can be verified with the scan tool, but “proof-of-flow” to and from the cooler requires a Sonnax SonnaFlow® flow meter. Click here to view flow charts for diagnosing problems in many units during a road test or on a dynamometer. Just because the valve body thermistor registers above 150°F or 180°F, it does not verify the flow control valve is completely open on the thermal type or completely closed on the pressure relief type.

Note: If the scan tool temperature continues to rise, this may indicate an excessive converter slip rate or insufficient cooler flow. Both conditions can be related to thermal or pressure control valves.

On the clutch-to-clutch shifting 6-, 8-, 9- and 10-speed transmissions, the bushings are critical to shift quality. Bushing clearance affects backfill or clutch balance piston pressure. If cooler flow is low, then bushings wear, so a malfunctioning “cooler control” element may eventually lead to a harsh shift complaint.

Related Units

Related Parts

Required

Recommended

Required

Recommended

42RLE • 45RFE • 545RFE • 68RFE • 722.6 • JF011E (RE0F10A)

Thermal Bypass Eliminator Kit 72760-02K

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.