Wear in Magnesium Transfer Case Housings

Gregg Nader

Transfer cases with magnesium housings include but are not limited to: the Ford/BorgWarner 4405 and 4411, and the 1999 and newer GM/New Venture 136, 149, 236, 246, 261 and 263 models. The type of magnesium alloy dealt with here is AZ91D, which is commonly used in these and other automotive applications. Wear in the Ford/BorgWarner (BW), typically causes engagement issues and rear seal leaks, while the GM/New Venture (NV) units show up with pinhole leaks in the housing and a loss of fluid. Magnesium transfer cases can be identified by the letters “Mg” inside a triangle cast on the outside of the housing.

First, a little background about magnesium. It is the eighth most abundant element in the earth's crust and the lightest structural material. It is 75% lighter than steel and 33% lighter than aluminum. Its light weight and reasonable strength make it a popular material for automotive engineers trying to trim weight from vehicles. In the BorgWarner transfer case application, 10 pounds were saved by using magnesium vs. aluminum. A common perception is that magnesium corrodes easily. However, the bare material actually rates better at corrosion resistance than aluminum. Where magnesium has a problem is when it is close to other metals and salt. The result is “galvanic” corrosion, which can rapidly corrode magnesium.

If you have worked on many of these units from areas with salt-treated roads, you’ve surely seen the external case material corroded away. To deal with galvanic corrosion, magnesium transfer cases use separators and special coatings on bolts, and even have special contours so that road debris (salt) is less likely to compact into small spaces. One other interesting fact about magnesium: it is a metal that can burn. When burning, it does not require oxygen to support combustion and water can actually feed the reaction. Class D fire extinguishers and smothering with sand are recommended to put out fires, so before machining or welding, take necessary precautions and be aware of what you are dealing with.

What about the wear? Both the BW and NV housings are notorious for fretting-type wear when internal moving parts contact the magnesium. In addition to sliding movement, this also includes parts that do not need to move but, due to normal clearances and vibrations, have some amount of relative movement between the part and the magnesium. Bearing races, shafts, retaining rings, pump locating arms and even metal “anti-wear” inserts all wear away the magnesium to some degree. Both BorgWarner and New Venture have other similar transfer cases made with aluminum housings. Wear on these aluminum versions is just not an issue like it is with the magnesium versions. The simple answer is that the magnesium versions wear more because magnesium is not as hard as aluminum.

This was demonstrated by a study that appeared in the Journal of Materials Processing Technology. To investigate how this relates to transfer case wear, I collected samples of both aluminum and magnesium transfer case housings from both GM and Ford. The samples were tested for hardness at room temperature and at 200 degrees Fahrenheit. Figure 1 is for reference only, and is a general guide to material hardness using the common Rockwell B & C hardness scales.

Figure 2 shows hardness testing results of actual transfer case housings. Significantly, not only is magnesium generally softer than aluminum, but at 200°F operating temperature the difference is even more dramatic. Compared to aluminum, the magnesium is as much as 40.1 points lower (softer) on the Rockwell B scale! In addition to hardness testing, we have also performed accelerated wear testing of different materials against magnesium. The results indicate that materials harder than magnesium will contribute to abrasive/fretting wear of the magnesium housings.

My conclusion is that magnesium is dramatically softer than aluminum in comparable applications and the difference is even greater at vehicle operating temperatures. Due to the relative softness of the AZ91D cast magnesium, any material that is harder than the magnesium (i.e. steel or aluminum) is abrasive or has sharp edges that will wear into the magnesium housings and create the type of wear we typically see in these units. Repair options should focus on eliminating the movement between harder/abrasive components and the magnesium housing (which is not always practical), or isolating the moving part with a non-abrasive, low-friction material that is softer than the magnesium itself.

Related Parts

Required

Recommended

Required

Recommended

New Process 230 & 240 Series

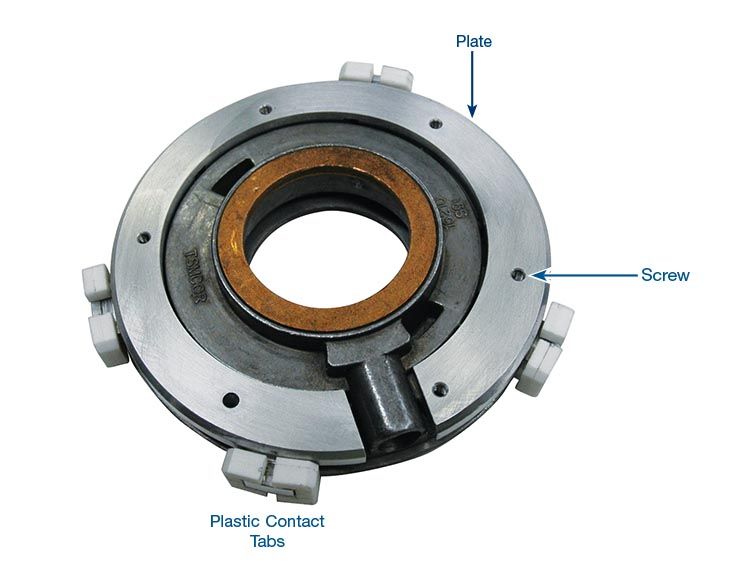

Transfer Case Pump Plate Kit 100246-02K

NP 136, 149, 236, 246, 261, 263

-

Helps cure:

- Rear housing wear

- Damaged transfer cases must be scrapped

- Pin-hole oil leaks in rear transfer case housing

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.