February 26, 2021

700-R4 (4L60) Performance Transmission Build Guide

Gregg Nader

In 1939 Cadillac and Oldsmobile became the first manufacturers to utilize a fully automatic transmission in a production vehicle; they named it the Hydra-matic, which would later be named the Turbo Hydra-matic. It was developed for rear-wheel-drive vehicles and had four Forward speeds plus Reverse. It used a hydraulic system combined with a mechanical planetary system to achieve each shift without input from the driver. Fourth gear was not overdriven as later units would become. The hydraulic system locked or unlocked different parts of the planetary system in each gear to achieve the correct gear ratio based on the speed and load of the vehicle. There was no mechanical link between the engine and the transmission, this was made possible by the fluid coupling.

The Hydra-matic was also used by smaller manufacturers such as Hudson, Nash and Lincoln, which did not have the resources to develop their own automatic transmissions. There were no competitors until 1948, when Buick released their Dynaflow automatic that included a torque converter instead of a fluid coupling to multiply torque. BorgWarner joined the game in 1958 with a 3-speed. In 1966 GM introduced the first front-wheel-drive vehicle with an automatic transmission: the Oldsmobile Toronado, which had three speeds. ZF Friedrichshafen AG, or ZF for short, introduced their version of a 3-speed automatic in the late 60's.

In 1968, Honda started to compete with other automatic-equipped, domestic vehicles in the U.S. Having trudged through the tens of thousands of patents that BorgWarner, GM and others filed, Honda developed a 2-speed, front-wheel-drive automatic transmission they named the Hondamatic. It made its debut in the 1968 N360 AT, which had the smallest engine an automatic vehicle had ever had: a 354cc two-cylinder putting out 31HP. What made the Hondamatic unique from other transmissions was that it did not use planetary gears, but rather individual gears on parallel axles. Each gear ratio was activated by a different clutch pack. Eliminating the use of planetary gears allowed for less friction and better efficiency, which was crucial considering the small engine.

The general shape and size of vehicles changed drastically after the 1973 oil crisis and the introduction of the Corporate Average Fuel Economy (CAFE) standards in 1975. Auto manufacturers were required to produce an average of 20mpg across their model lineup. Vehicles slowly switched from primarily rear-wheel-drive models to primarily front-wheel-drive to save weight. Automakers also reduced the size and weight of vehicles to help raise the gas mileage. Both of these changes had a profound effect on the design of transmissions, especially in small, front-wheel-drive cars. Less space was available for the transmission and there was a new focus on using lighter-weight materials like aluminum for transmission cases and valve bodies.

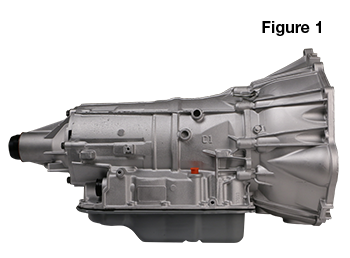

Trucks and rear-wheel-drive cars utilized an overdriven 4th Gear and a torque converter, but continued to use the 4-speed planetary design for years to come until the manufacturers needed even more efficiency from their transmissions. They needed to move on from the standard, 4-speed automatics and start adding more gears to further increase efficiency. Development came very swiftly in the coming years as demand grew even larger for fuel efficiency. In 1991 the first 5-speed automatic made by ZF was introduced in the BMW E36 320i/325i and E34 5 Series. GM developed their own rear-wheel-drive, 5-speed transmission for their medium-duty line, the 5L40, in 2000. Another gear was added by GM when they introduced the 6-speed 6L45/6L50 in 2007 for their medium-duty, rear-wheel-drive line. GM introduced the 6-speed 6L80 (Figure 1) for the rear-wheel-drive, heavy-duty line in 2006, finally replacing the 4-speed 4L60-E series they had used since 1992 (Figure 2), which itself was a modernized version of GM’s original 4-speed unit— the 4L60 (700-R4) — that debuted in 1982.

| Figure 1 – 6-Speed 6L80 Transmission |

|---|

|

| Figure 2 – 4-Speed 4L60-E Transmission |

|---|

|

In the next few years, Ford and Dodge followed suit and switched to 6-speeds in both front- and rear-wheel drive platforms as well. ZF developed an 8-speed 8HP70 in 2008, with GM following suit in 2014. Adding another two speeds, GM introduced the 10-speed 10L90 in 2017.

Now that we have covered traditional, planetary transmissions, let’s take a look at a few innovative units over the years.

What about a transmission with no actual gears? Once a concept imagined by Leonardo De Vinci in 1490 — the Continuously Variable Transmission, or CVT for short — uses a set of variable-diameter pulleys with a steel or composite belt connecting them to provide an infinite amount of gears. Because the transmission is not locked into a set group of gear ratio, the engine can be kept at a lower RPM range at cruising speeds, which increases gas efficiency.

The first production vehicle available in the U.S. with a CVT was the Subaru Justy in 1989. Nissan followed suit shortly after that, and utilized it in the majority of their small- to mid-size cars and sport utility vehicles. Fast forward to today, and it is used by most manufacturers in one or more of their models. It has a low manufacturing cost to produce and does not take up as much space as a traditional planetary transmission. A concern about this transmission has been the longevity, as the belts are known to break down over time, which require a full rebuild once the belt degrades. No manufacturer has been able to successfully use one in a heavy-duty or truck application because of the low tolerance this system has to vehicle weight.

The final transmission type we will look into is the Dual Clutch Transmission (DCT), also known as Direct Shift Gearbox (DSG). This transmission can be described as a cross between an automatic and a manual shift transmission. Using two separate clutches to control the odd and even gear sets, it can be used in fully-automatic mode, or in some cases semi-automatic mode, allowing the driver to perform the shifts through paddle shifter levers on the steering wheel. Because there are two separate clutches, one clutch is always preparing to engage to make the next shift, resulting in shift times that are faster than both automatics and manual transmissions .

The DCT was a concept that Adolphe Kegresse of France came up with in 1935. Although it never materialized at the time, it was later revisited by Porsche, which installed their version — named the Porsche Doppelkupplungsgetriebe or PDK for short — in their 956 race car to test and later utilize in their 962 race car. Audi utilized the PDK in a Quattro S1 in 1985 to compete in rally races. Volkswagen installed their own DCT in the 2003 Golf R32, which was the first production vehicle in the U.S. to have one. Shortly after 2003, the DCT was used in the Audi TT, several different BMW models and even the Ferrari California.

The ability for more driver interaction than typical automatics and faster shift times than manual transmissions have made the DCT the desired choice by many for an automatic option in sports cars. The 2020 Chevy Corvette C8 is evidence of this, as it is offered with an 8-speed DCT as its only transmission option. In my opinion, the DCT brought to the market what other automatics have not, which is excitement and performance. It definitely makes you wonder what is next in the progression of automotive transmission technology.

Be sure to read a more in-depth look at the functionality of 4L60 and 4L60-E series transmissions in The Evolution of Automatic Transmissions Part 2: The Inner Workings of Hydraulic Planetary Transmissions.

Jason Larochelle is a Sonnax product support representative. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.

February 26, 2021

Gregg Nader

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.