August 16, 2019

How to Identify Ford 6R140 Torque Converter Features & Avoid Application Pitfalls

Steve Jaussaud

The Ford 6R140 was introduced in 2010 (2011 model year trucks) as a 6-speed used in Super Duty® gas- and diesel-powered applications. Today, these units are in high-value, hardworking trucks at the peak of the repair cycle. Aftermarket programming (especially with the diesel variants) is pulling additional power from the engines, putting further loads to the downstream torque converter and drivetrain components. Fleets, businesses and individuals work these trucks hard and will spend the money needed to fix them correctly. This article will cover some of the unique 6R140 features from previous TASC Tech Tips (including The Curious Case of the Missing 6R140 Forged Billet Cover and Ford 6R140 Separator Plate Identification – How to Identify Changes & Interchangeability), the strategy used to operate the converter clutch and some pitfalls that transmission rebuilders can look out for as they select a converter to use with their rebuild.

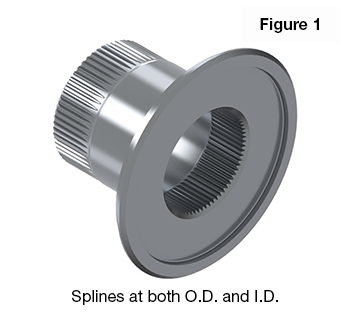

The first thing you will notice about the converter is the size and weight. The converter hits the scales at approximately 70 pounds dry. After that, you will notice that the impeller hub is large, thin-walled and has splines at two locations: the leading edge of the O.D. and the base of the I.D. of the hub (Figure 1). O.D. splines run the transmission pump while the I.D. splines engage the PTO system. Look for damage on both the outside and inside (it’s a sealing surface, too) of the impeller hub, and always replace the drawn cup needle bearing in the transmission pump during rebuild (Figure 2).

| Figure 1 – 6R140 Replacement Impeller Hub | Figure 2 – Converter Hub Support Pump Bearing |

|---|---|

|  |

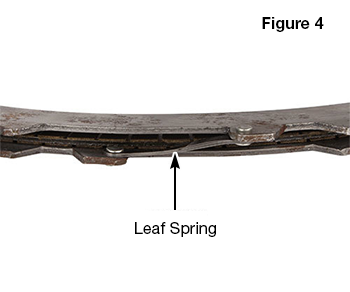

This is also a captive clutch type of converter, and to gain access to the friction elements in the unit, a converter rebuilder has the additional step of cutting out the contoured stamped backing plate (Figures 3 & 4). It’s accurate to say, in both size and design, the 6R140 presents a formidable challenge to converter rebuilders. Sonnax FD-CP-20K is a great kit that offers forged internal components and makes it a relatively easy build for a converter rebuilder. While the kit does not include a forged billet cover, it does provide for upgraded performance and increased durability.

| Figure 3 – Converter Stamped Backing Plate | Figure 4 – Leaf Spring |

|---|---|

|  |

After the converter is cut open, the stamped backing plate in the 6R140 converter still needs to be cut out of the front cover assembly. As a captive clutch converter, properly fixturing and welding this contoured plate back into the cover can be challenging. | Even after cutting the backing plate out, the clutch plate is still captive, sandwiched between steel plates. These steels are riveted together, connected by problematic leaf springs that are prone to breakage. |

Besides having a variety of captive components inside the converter, the way the 6R140 converter clutch applies is also unique. In most other converters, the friction element reacts against the inside surface of a stamped steel OE front cover. That’s why forged covers are beneficial to so many converters: the surface that the clutch rides against is a stamped steel, prone to flexing and warpage that causes premature clutch failure. With Chrysler 48RE converter, for example, you know you need a forged cover if the unit is subject to any kind of stress. But the 6R140 is different. The clutch plate reacts against a separate backing plate in the converter, and the converter clutch never touches the front cover! Before you decide to spend for a 6R140 converter that has been modified with a forged billet cover, make sure it will actually provide some benefit. Again, it’s worth noting that there are parts and kits available to converter builders that will provide a rigid, forged surface for the clutch plate to ride against forged cover. But these aftermarket forged components aren’t something you can see once the converter has been rebuilt and welded back together, so you end up with a converter that’s “forged on the inside.” This can be a challenge.

When it comes to the strategy as to how and when the OE programming applies and releases the converter clutch in the various 6R140 applications, it’s a very active unit. Within normal operating temperatures and depending upon conditions and inputs, the clutch can apply as early as 2nd Gear — at 18 mph. It can apply and release often on both upshifts and downshifts. Analysis of scan tool recordings during drive cycles shows some brief pulsing of the clutch upon apply, but for all intents and purposes, this really functions as an on/off clutch. Also, when using the PTO function, the clutch can fully lock, depending upon transmission oil temperature and other inputs.

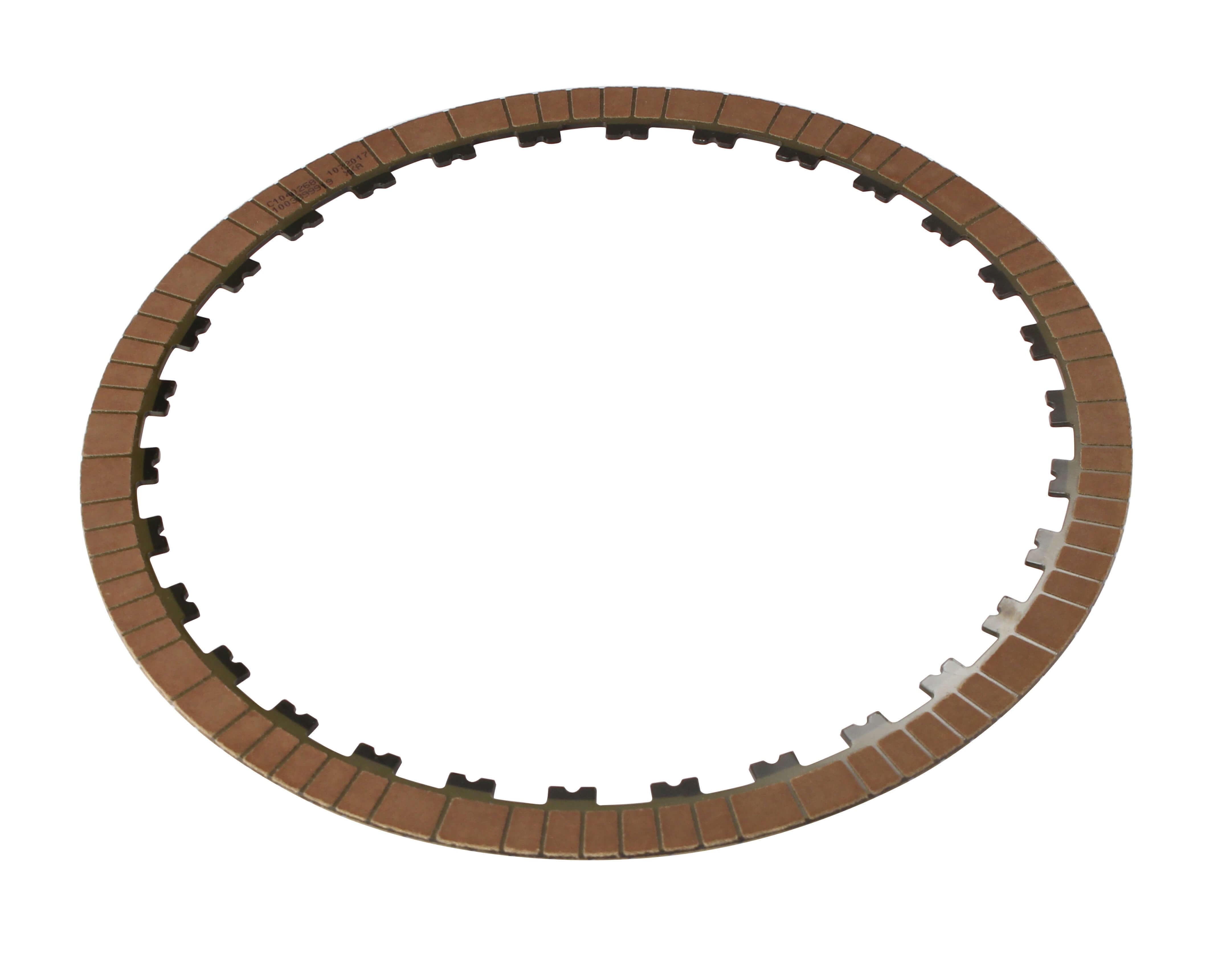

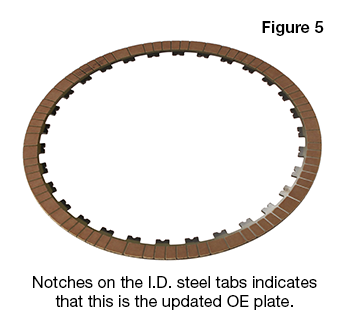

The clutch plate that is used in the 6R140 converter is a segmented and double-sided plate (Figure 5). BorgWarner was the original supplier to Ford, and there has been an update to the plate since the original release. Luckily, the updated BorgWarner OE plate is available through aftermarket channels. There is only one plate in the unit, and as long as controls are good and the apply and reaction surfaces remain rigid, flat, and parallel, then the clutch plate holds up quite well.

| Figure 5 – Double-Sided, Segmented OE Clutch Plate |

|---|

|

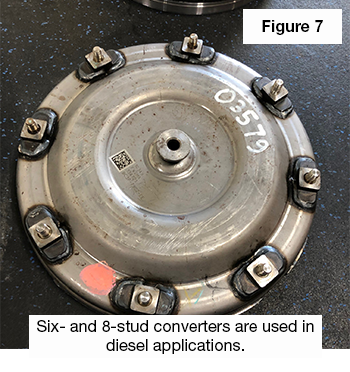

Transmission shops will also notice that there are 4-stud, 6-stud and 8-stud versions of this converter (Figures 6 & 7).

| Figure 6 – 4-Stud Converter Cover | Figure 7 – 8-Stud Converter Cover |

|---|---|

|  |

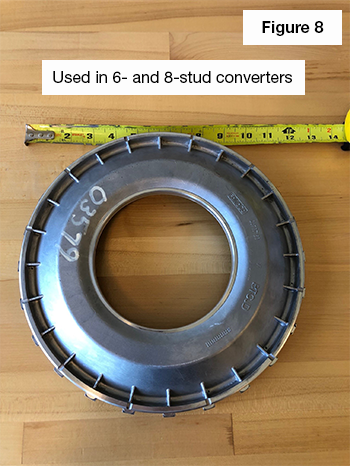

The 4-stud version is a higher stall/K factor used in the lower torque-rated gas engines. The 6- and 8-stud versions both come in diesel applications, and there has been some confusion around these. Other than the difference in stud count, the 6- and 8-stud versions are identical internally. When cutting the 6- or 8-stud units apart, they both have the large clutch apply piston (Figure 8). The problem for a transmission shop is that, if it orders a reman converter from its supplier (in advance of them removing the transmission), it’s unknown if a 6- or 8-stud unit will be sent. And because the flex plates are specific to the stud count on the cover, the converters are not interchangeable without changing the flex plate.

| Figure 8 – Converter Clutch Apply Piston |

|---|

|

Sometimes a transmission shop will mistakenly decide to install a 4-stud converter after removing an 8-stud unit. They have a 4-stud converter in stock and can see that a 4-stud unit will bolt up. (Every other hole in the flex plate will be blank.) But what the shop does not know is that the piston in the 4-stud converter (Figure 9) has a much smaller apply area than the piston in the 6- and 8-stud units. So, they install the 4-stud converter and test drive the truck. The stall speed isn’t quite right, but it’s not terrible. The converter locks up sufficiently, and they deliver the truck to the customer. However, the first time the converter clutch is tasked with some heavy pulling or aggressive driving, it fails due to the lack of apply pressure from the small piston. You can only install a 4-stud converter in a vehicle that had a 4-stud to begin with. A 4-stud converter may fit in a diesel with an 8-stud flex plate, but the converter clutch will soon fail in use.

| Figure 9 – 4-Stud Apply Piston |

|---|

|

In conclusion, the converter in the 6R140 is a hefty unit that presents challenges to both transmission and converter rebuilders. There are great upgrades available, like the Sonnax Smart-Tech® converter clutch kit, to converter rebuilders that will fortify the converter for additional capacity and durability, but transmission shops shouldn’t necessarily be looking for a converter with a billet cover as proof it’s been upgraded. Just because a 6R140 converter has that shiny (and expensive) billet cover doesn’t necessarily mean that the converter has been upgraded. And critically, know when you can — and cannot — interchange the 4-, 6- and 8-stud variants of this converter. Having this knowledge upfront will help ensure transmission builders sell the correct upgraded components for rebuilding a customer’s hardworking transmission and converter.

Steve Jaussaud is the Sonnax torque converter product line manager. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of industry technical specialists, transmission rebuilders and Sonnax technicians.

Learn More

May 11, 2022

Ford 6R140 Separator Plate Identification – How to Identify Changes & Interchangeability

Eric Streed

August 15, 2022

Troubleshooting Ford 6R80 & 6R140 Timing-Related Shift Issues

Jim Dial

Related Units

Related Parts

Required

Recommended

6R140

Impeller Hub FD-90-140G

- Material: Chromoly

- PTO Drive: Internal Spline

- Pump Drive Style: External Spline

- Hub Mount: Flanged

- Height: 2.800"

- Flange Outer Dia.: 4.500"

- Journal Dia.: 2.508"

- Assembled Height: 2.672"

Required

Recommended

6R140

Converter Hub Support Pump Bearing 126202

- Outer Dia.: 2.787"

- Inner Dia.: 2.484"

- Thickness: 0.547"

-

Helps cure:

- Pump noise

- Bearing failure

- Loss of lube oil

Required

Recommended

6R140

Clutch Plate FD-CP-140A

- Tab Style: Internal Flat

- Outer Dia.: 11.500"

- Inner Dia.: 9.770"

- Thickness: 0.118"

- Tab Count: 30

Required

Recommended

6R140

Smart-Tech® Converter Clutch Kit FD-CP-20K

- Tab Count: 24

- Outer Dia.: 12.730"

- Inner Dia.: 12.220"

- Thickness: 1.425"

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.