November 20, 2020

Hydraulics Fundamentals Part VII: AFL/Solenoid Modulator Valves

Read Part I , Part II, Part III, Part IV, Part V and Part VI of the Hydraulics Fundamentals series.

Solenoids need reliable oil supply to function correctly. The valves responsible for regulating oil supply to the solenoids are referred to as actuator feed limit (AFL) valves, solenoid modulator or solenoid regulator valves, depending on the manufacturer. Correct AFL valve function is critical for shift operation and feel. A worn or stuck valve can lead to solenoid codes, wrong gear starts, clutch/band failure and harsh or soft shifts.

To understand the critical nature of AFL valves, it is beneficial to understand general solenoid function, which is explored in previous articles in the Hydraulics Fundamentals series and other Sonnax tech articles, such as “Flow Control: How Solenoid Design Influences Clutch Circuits.” Broadly speaking, solenoids control shifts and shift timing by routing or modulating oil through the valve body to the various clutch circuits, and apply and release components. Flooding with or depriving the solenoids of oil may lead to problems with shifts, shift timing, solenoid codes and malfunction, slipping, flares and wrong gear starts.

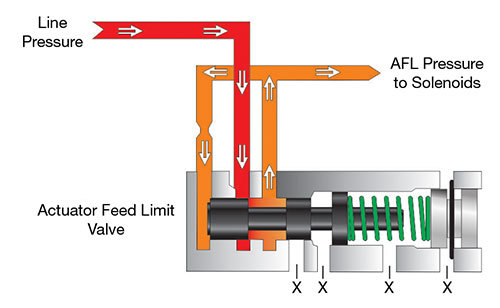

AFL valves are typically fed line pressure and output a regulated AFL pressure that is routed to the balance end of the valve through an orifice. In GM 4L60-E and 4L80-E transmissions (Figure 1), line pressure is regulated at approximately 115 psi and fed to the shift solenoids, pressure control solenoid, TCC solenoid, 3-2 control solenoid and the 2-3 shift valve lineup.

| Figure 1 — GM 4L60-E AFL Valve |

|---|

|

The large reaction area on the spring end of the valve results in side-loading, making the bore especially susceptible to wear. A worn or stuck valve can cause erratic pressures, restrict oil to the solenoids or flood them, depending on where the valve is worn or stuck. Often in the 4L60-E and 4L80-E, worn AFL bores result in low actuator feed and line pressures. The bore should be addressed to eliminate wear, as leakage results in flooded or starved solenoid feed and ultimately a loss of line pressure. Loss of line pressure can overwork pumps, and, because of hydraulic circuitry, cause 1870 or TCC codes.

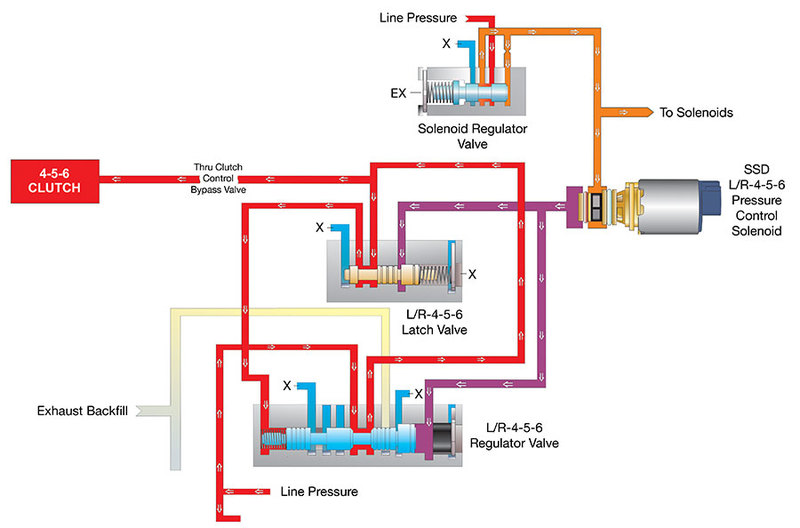

Ford’s 6F35 is known for solenoid regulator valve issues as well. Just as in the 4L60-E and 4L80-E, line pressure is routed to the solenoid regulator valve and is regulated into solenoid feed pressure (Figure 2). This valve is also susceptible to side-loading, which has been a major issue with this family of transmissions. Transmission slips, flares and even loss of 4th through 6th Gears are indications that the solenoid regulator valve may be failing.

| Figure 2 — Gen. 1 6F35 4th Gear |

|---|

|

Oil from the solenoid regulator valve is fed to shift solenoid D. In Gears 4 through 6, shift solenoid D will route pressure to the Low Reverse/4-5-6 regulator valve. That moves the Low Reverse/4-5-6 regulator valve into position to route line pressure to the clutch control bypass valve. If the solenoid regulator valve wears — in the Gen. 1 6F35, they tend to wear a lot — it may not supply enough oil to shift solenoid D. This may result in the Low Reverse/4-5-6 regulator valve being out of position and can restrict oil to the 4-5-6 clutch, resulting in bad shifts and potentially burnt clutches. When dealing with transmission slips, erratic shifts, flares or even loss of Gears 4 through 6, it is a good idea to inspect the solenoid regulator valve for damage.

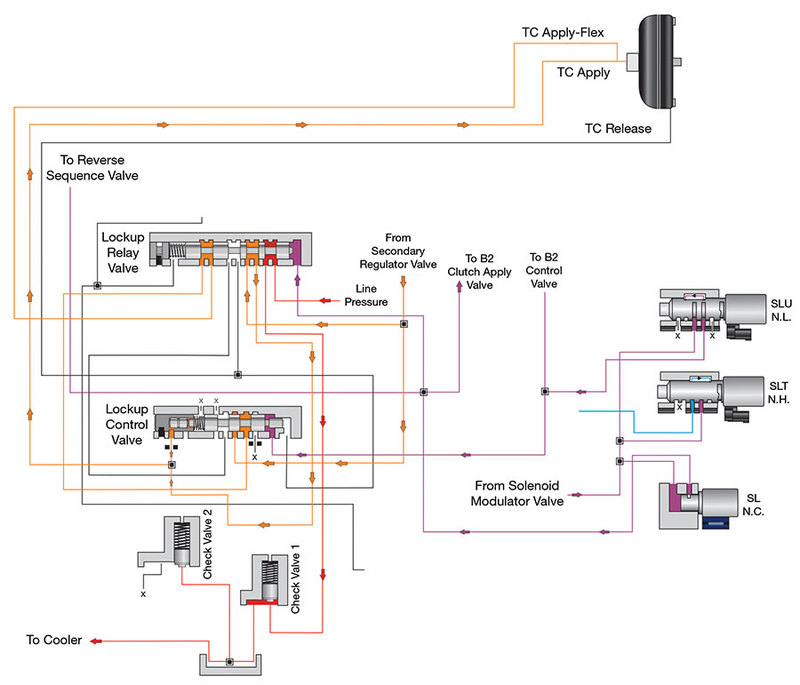

Toyota generally refers to these valves as solenoid modulator valves. In Toyota/Lexus U660/U760 transmissions, the solenoid modulator valve directly supplies oil to the SL solenoid, SLT solenoid, SLU solenoid and the sequence valve. This hardened steel valve supplies several modulating solenoids, so it is prone to high-frequency movements, often resulting in bore wear. It is involved in all shift circuits, and a worn bore or stuck valve can cause solenoid malfunction and shift issues.

In addition to supplying oil for control of the clutches in the transmission, the Toyota solenoid modulator valve supplies the solenoids involved in torque converter control (Figure 3).

| Figure 3 — Toyota/Lexus U760 TCC Apply |

|---|

|

The SLU and SL solenoids, respectively, help control the positions of the lockup control valve and lockup relay valve. If the solenoids are not supplied oil correctly, function of the lockup relay and control valves may be affected, and can result in improper lockup control. Premature lockup or TCC shudder and slip may be caused by a faulty solenoid modulator valve.

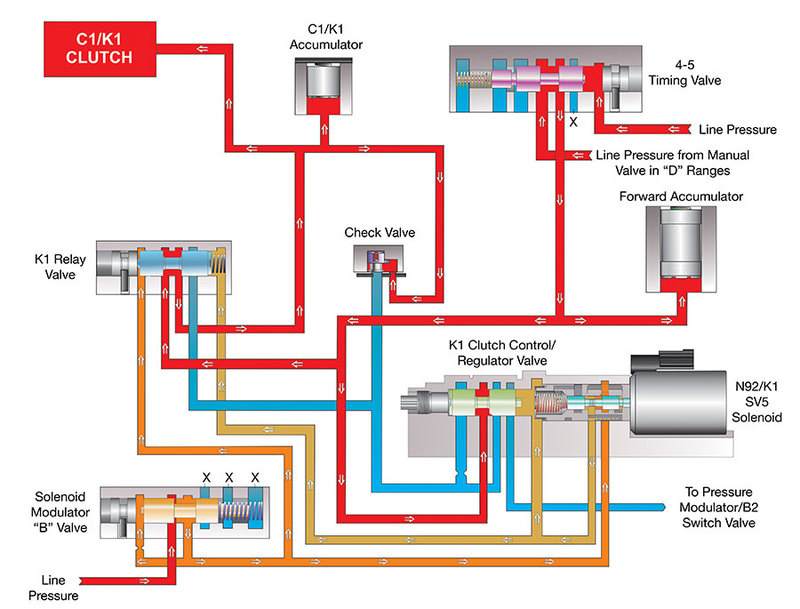

Knowing your transmission oil circuit is helpful for diagnosing issues. The VW/Audi 09G is unique in regards to solenoid feed modulation. It uses two, nearly identical solenoid modulator valves to regulate oil to various solenoids. Solenoid modulator “A” supplies oil to solenoids controlling the K2, B1 and K3 circuits, as well as the ON/OFF solenoids N88 and N89, which route oil to several switch/relay valves. Solenoid modulator “B” supplies oil to the TCC solenoid, line pressure mod (EPC) solenoid and solenoid N92, which is responsible for the K1 circuit (Figure 4).

| Figure 4 — Audi/VW 09G K1 Circuit |

|---|

|

A common complaint in these units is clunks on downshifts. When the solenoid modulator “B” valve wears, it often results in low solenoid feed pressure. This can cause a slower stroke of the K1 regulator valve, resulting in a slow, out-of-sync system response and a slow reapply of the K1 clutch. The transmission may attempt to adapt and adjust the duty cycle on the N92 solenoid, causing the often-felt clunk.

As you can see, a faulty AFL valve can be the culprit for a wide range of issues in the transmission and torque converter. Transmission slipping, shift issues and solenoid codes are often a red flag to check the AFL valve. Knowing your transmission’s hydraulic circuit — and solenoid circuits in particular — can be very helpful when identifying the underlying cause. AFL valves are often simple lineups, but very active and important for the overall function of the transmission and torque converter.

Neal Axelrod-Adams is a Sonnax design engineer. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.

Learn More

January 28, 2019

Hydraulics Fundamentals Part I: Main Pressure Regulator Valve Line-Ups

Zachary Richardson

February 26, 2019

Hydraulics Fundamentals Part II: Accumulators & Shift Feel

Maura Stafford

March 26, 2019

Hydraulics Fundamentals Part III: Secondary Regulators

Jim Dial

May 03, 2019

Hydraulics Fundamentals Part IV: Converter Clutch Control

Bob Warnke

March 03, 2020

Hydraulics Fundamentals Part V: Manual Valves

Jim Dial

March 26, 2020

Hydraulics Fundamentals Part VI: Converter Limit Valves

John Varvayanis

June 08, 2020

Hydraulics Fundamentals Part VIII: Check Valves

December 17, 2020

Hydraulics Fundamentals Part X: Shift & Relay Valves

Jim Dial

January 25, 2023

Uncovering the Root Cause of Pressure & Complaints – The Critical Role of Solenoid Modulator & AFL Valves

Maura Stafford

Related Units

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.