September 10, 2019

GM 6T40 & 6T70 Drum Saver Kits: Unbeatable Protection Against 3-5-R Failures & Comebacks

Click here to watch a video on

3-5-R failures and Sonnax drum saver kits.

Предпочитаете смотреть видео на русском? Нажмите здесь, чтобы узнать о наборах Sonnax.

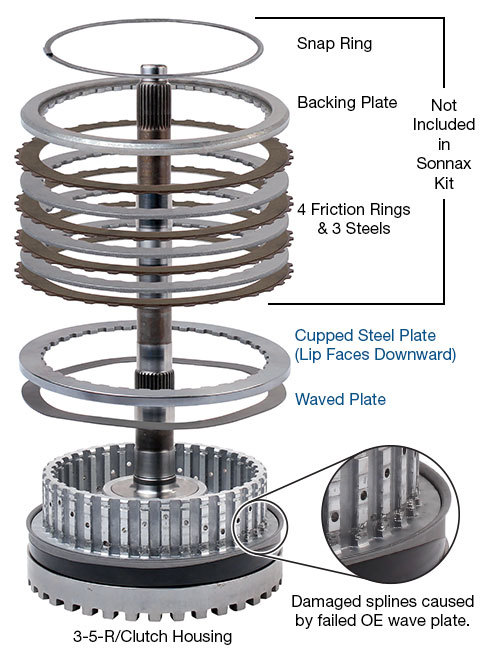

Anyone who has ever worked on GM Gen. 1 6T40/45/50 and 6T70/75 transmissions is familiar with the problem of the 3-5-R waved plate breaking in ’07–’09 models. It’s not uncommon in later units, either. When the plate breaks apart, it usually damages the drum splines, requiring an expensive new housing. Even if the plate hasn’t failed yet, you know you can’t risk leaving it in there, so this is an area that always gets attention during a rebuild.

To protect the plate and drum from failure and make it easy to salvage even damaged drums, Sonnax now offers a simple and affordable solution: 3-5-R drum saver kits 144555K and 124555K. The combination of an improved waved plate and custom steel plate work together for top-notch protection against warranty comeback.

When waved plate failure first became a chronic issue, GM did try to address the problem. They determined breakage was due to the plates being insufficiently stress relieved, so their solution was to shot-peen the plates to reduce the stress points that can lead to premature failure. Installing this updated OE waved plate in early-model transmissions has become standard operating procedure throughout the rebuilding industry. Unfortunately, both stock and rebuilt units with the newer plate installed (including Gen. 2) are still failing in the field, causing warranty comebacks for builders. While the updated plate is more reliable than the older version, it doesn’t eliminate all worries about whether the unit on your bench will end up as an expensive do-over. This brings up two questions:

- Can you ensure the problem doesn’t happen again while your build is under warranty?

- Is there a way to salvage drums that have already been damaged by a broken plate?

Why Does the Waved Plate Break?

Many stress points for the waved plate can be eliminated by shot-peening. However, the design of the updated OE plate retains many of the stress points that allow it to break — namely all the teeth. Take a look at the broken plates in Figure 1.

| Figure 1 – Broken OE Waved Plates |

|---|

|

These are representative of EVERY broken OE plate Sonnax studied while researching a solution to this problem. Notice they are all separated exactly at a tooth corner (a common stress point). Even OE plates that look OK to the eye can develop micro fractures here and be on the verge of failure. To prevent broken waved plates in 6T40/45/50 and 6T70/75 units, a different design is needed that eliminates these stress points once and for all.

Stopping the Failure Cycle

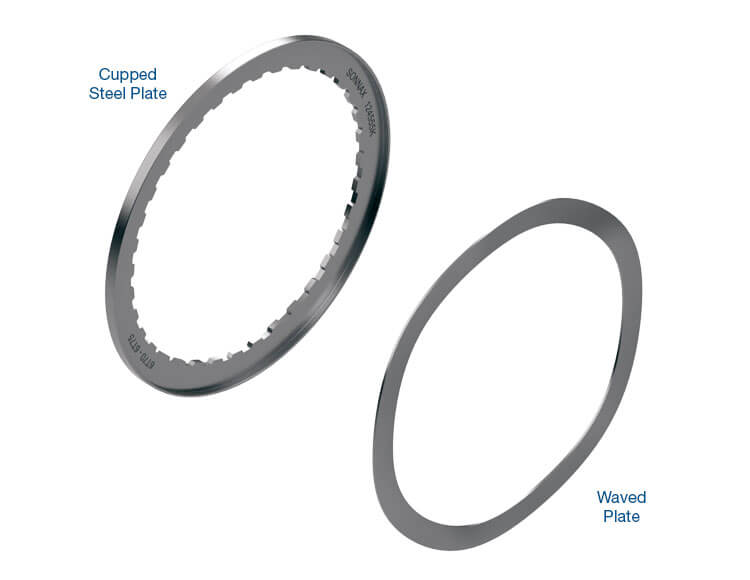

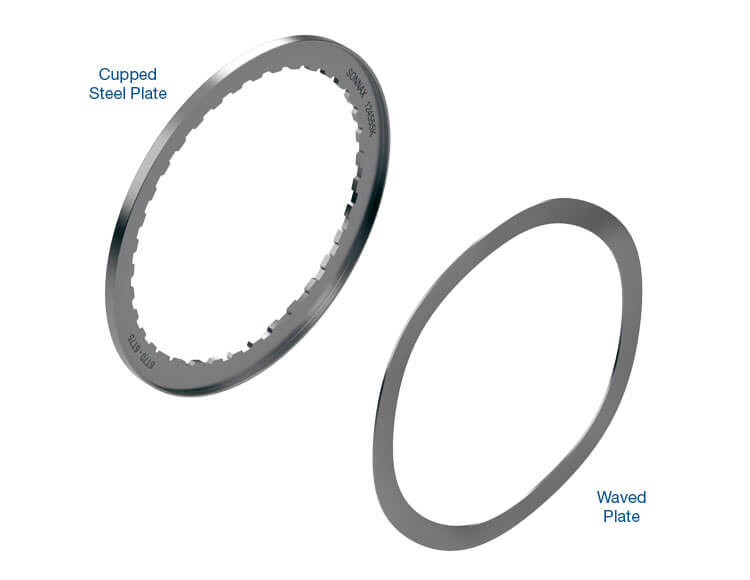

The waved plates in the Sonnax drum saver kits are shot-peened for added durability like the updated OE version, but we took the whole concept a step further by eliminating virtually all stress points: There are ZERO teeth on the Sonnax waved plate.

Because there are no teeth, we need a way to position and guide it on the drum. That’s where the other part of the kit comes in: a custom, cupped steel plate.

This is a billet piece — not a thin, stamped plate — and it fits together perfectly with the Sonnax waved plate. The cupped steel plate fits right over the top of the waved plate to secure it in place on the drum (Figure 2).

| Figure 2 – 3-5-R with Damaged Splines |

|---|

|

It’s the same thickness as the bottom steel in the clutch pack (which is discarded in favor of the Sonnax steel), giving you perfect clutch clearance every time — PLUS great heat dissipation.

The cost of a failed drum while your rebuild is still under warranty is way too high with OE waved plates — the early-style or the late-style. These drums aren’t cheap, and neither is pulling the tranny back out, tearing it down and installing new parts on your own dime. Adding a Sonnax drum saver kit to every build guarantees no more comebacks due to broken OE waved plates.

Salvaging Damaged Drums

These same two parts also will save you the hassle and expense of replacing a failed drum. If you have a unit on your bench with a broken OE waved plate and the drum splines are all chewed up as a result, there’s usually nothing to be done except source and install a new drum and OE waved plate, then cross your fingers. Because there are no teeth on the Sonnax waved plate, it can ride near the damaged spline area without interference; there is no danger of hanging up (Figure 2) like an OE plate would. This is so much faster and easier — not to mention less expensive — than buying a new drum and having to spend time transferring the shaft and piston over. Plus, you’ve got the best waved plate you can get in there to make sure your rebuild really lasts.

The next time you have one of these transmissions on the bench — early- or late-model, 6T40/45/50 or 6T70/75 — ask your distributor for a Sonnax 3-5-R drum saver kit. By preventing failure or helping you salvage a damaged drum, they will greatly improve the reliability of your builds for great insurance and peace of mind when working on these units.

Learn More

Related Units

Related Parts

Required

Recommended

6T70 (Gen. 1) • 6T70 (Gen. 2) • 6T75 (Gen. 1) • 6T75 (Gen. 2)

3-5-R Drum Saver Kit 124555K

-

Helps cure:

- Code P0776

- Flare shifts

- Harsh Reverse

- No Reverse

- 2-3 Harsh

- No 3rd

- 4-5 Harsh

- No 5th

Required

Recommended

6T40 (Gen. 1) • 6T40 (Gen. 2) • 6T41 (Gen. 3 6T40) • 6T45 (Gen. 1) • 6T45 (Gen. 2) • 6T46 (Gen. 3 6T40) • 6T50 (Gen. 1) • 6T50 (Gen. 2) • 6T51 (Gen. 3 6T40)

3-5-R Drum Saver Kit 144555K

-

Helps cure:

- Code P0776

- Flare shifts

- Harsh Reverse

- No Reverse

- 2-3 Harsh

- No 3rd

- 4-5 Harsh

- No 5th

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.