July 13, 2023

Troubleshooting RFE Overdrive Clutch Failure: Three Key Areas to Check

Caleb Perham

You may have noticed some similarities over the years in regards to a family of Chrysler transmissions that began with the Ultradrive 4-speed automatic in 1989. In its day it was fairly innovative, featuring clutch-to-clutch operation (no bands) and adaptive shift technology. Over time, the basic structure has developed into a variety of different models, some with 5- and 6-speed variations.

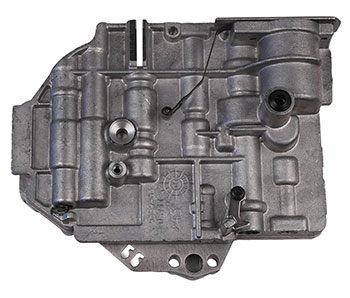

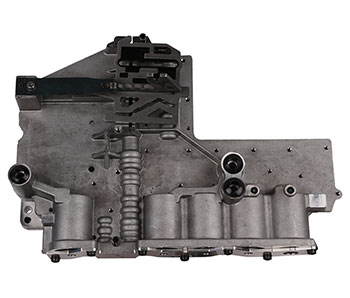

| Figure 1 | Figure 2 |

|---|---|

|  |

Because there are no bands, precise fluid control is critical for proper clutch application. In this system, control duties are handled by three primary elements: the solenoid pack, pressure switches and — the subject of this article — the solenoid switch valve. The main function of the switch valve is to direct fluid between the L/R clutch and TCC, but it also directs oil to the 2nd and OD clutches by means of two shuttle valves or “plugs” in the end of the bore. As wear develops in the bore, it is common for the switch valve and plugs to stick, which causes a variety of different symptoms. Among these are:

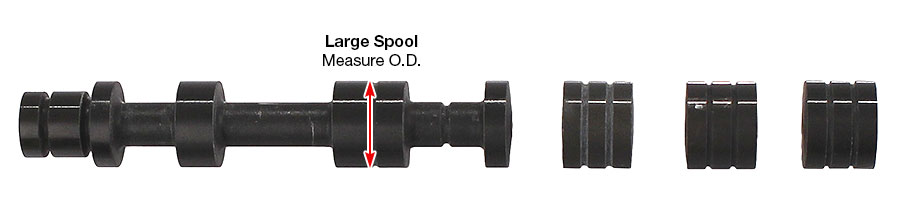

| Figure 3 | ||

|---|---|---|

| ||

| Valve Large Spool O.D. | Outer Plugs O.D. | |

| Original Design | 0.420" | 0.453" |

| New Design | 0.453" | 0.453" |

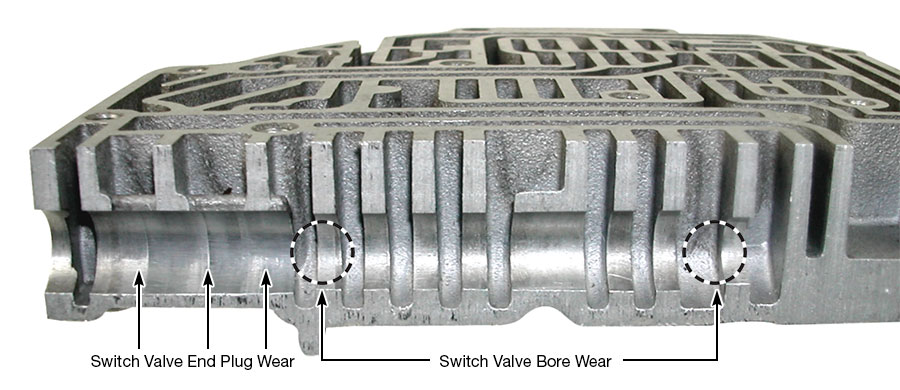

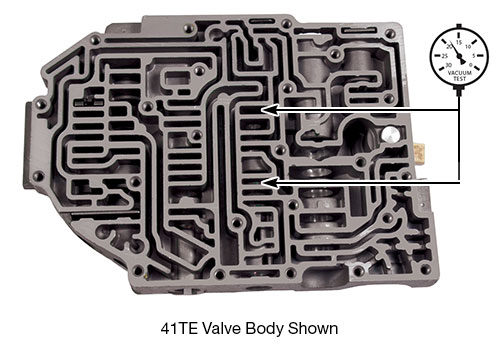

While in many cases the wear is obvious (Figure 4), vacuum testing is going to be your best bet in determining when a repair is in order (Figure 5).

| Figure 4 | Figure 5 |

|---|---|

|  |

The good news is that aftermarket solutions are available to correct the bore and its components; just make sure to measure the switch valve prior to making any repairs. The tooling required to perform this repair depends on properly identifying the large spool diameter of the switch valve. Using the wrong tooling setup can result in wasted time and irreparable damage to the valve body casting.

It’s common to see a few outlaw members in the family tree that need help finding the path of righteousness. In this case however, the problem is easily recognizable, and restoring order to the family is a fairly simple solution. Don’t you wish every family problem could be corrected that way?

Tory Royce is a Sonnax technical support specialist and a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.

July 13, 2023

Caleb Perham

Required

Recommended

Required

Recommended

Fits bores containing OE switch valve with .420" dia. large spool only.

Required

Recommended

Required

Recommended

Fits bores containing OE switch valve with .453" dia. large spool only.

Required

Recommended

Fits bores containing OE switch valve with .453" dia. large spool only.

Required

Recommended

Fits bores containing OE switch valve with .420" dia. large spool only.

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.